Regulating your clock is the process of making repeated, precise adjustments to its mechanism with the goal of enhancing its accuracy and ensuring it functions as a reliable timekeeper over an extended period.

The running of your mechanical clock is influenced by three key factors: neglect, friction, and the environment. These elements will determine whether your clock can maintain accurate timekeeping. The article ends with tips on regulating your clock and the effects of mainspring power on timekeeping.

Let’s look at each factor.

Neglect

Neglect is easy to understand: without proper care, a clock will lose its reliability as a timekeeper. Placing a clock in a sunny spot, especially in a hot window, can cause the case to age prematurely and dry out the movement. Setting a clock near a heat source, like a heating vent, can affect its performance. Transporting a weight-driven clock without securing the weights can result in broken case parts and shattered glass. Moving a pendulum clock without removing the pendulum can cause internal damage.

Additionally, turning the hands backward should be avoided unless the manufacturer specifically permits it in the clock’s instructions.

Friction

Each moving part of a clock must be in optimal condition. The gear train should move freely, but excess friction will negatively impact the clock’s performance. Regular lubrication is crucial to prevent this. Friction causes wear, and over time, wear can lead to costly and time-consuming repairs. As bushing wear accelerates, the clock’s functionality will deteriorate, eventually causing it to stop.

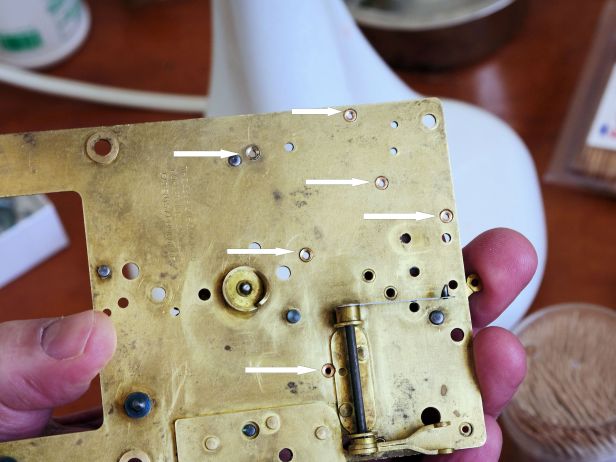

It’s good practice to inspect your clock’s movement every year or two and add oil if the pivots are dry. If you notice a buildup of thick, dirty oil around the pivot holes during your inspection, it’s time to service the clock’s movement. This can be done either by you, if you have the necessary skills, or by a clock specialist.

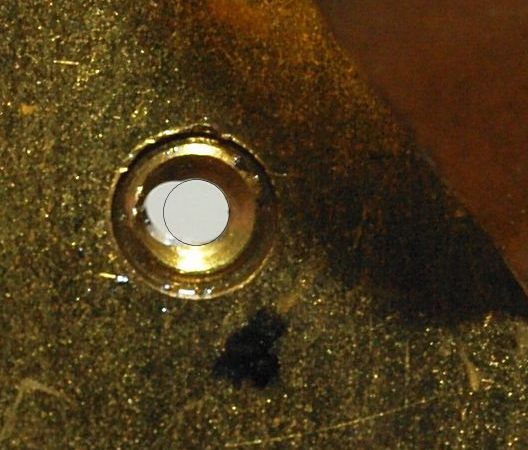

Once the lubricating oil is used up or dries out the clock continues to run but the wheels are running without lubrication in their pivots holes. Once the pivot holes are enlarged (see above) the gears begin to run too deep into each other and the clock eventually stops. In clock circles the proper function of one gear operating with another, smoothly is referred to as “meshing”. Once wear becomes a factor, winding the springs no longer helps, as the springs lack sufficient power, or the gears fail to mesh properly, preventing them from overcoming friction in the gear train.

This leads some owners to think the clock is stopping due to being “over-wound,” when in reality, it’s simply worn out, or there is so much debris and dried oil in the mainspring that it sticks and refuses to unwind.

Preventative maintenance can help avoid costly repairs.

Servicing a clock is a separate topic altogether but black or green oil around or in the pivot holes is an indication that re-oiling will be ineffective; dis-assembly and cleaning of the movement is necessary.

Mixing old, dirty clock oil with new oil will speed up wear, and adding more oil won’t improve its performance.

Environment

Changes in the ambient temperature of your environment will affect it’s timekeeping rate. It is quite common to make seasonal adjustments to your clock. If you are in a temperate climate such as my part of the world, humidity, and temperature changes have a noticeable effect on the rate-keeping of any clock. Increasing the ambient temperature will slow it down, from the expansion and lengthening of the pendulum rod (unless it has a compensating type pendulum).

Clocks perform better in the more controlled environment of a home, but damp basements, window sills, bathrooms, areas above heating elements or vents, garages, and other humid spaces are unsuitable for mechanical clocks. Harsh environments can damage both the movement and the case, leading to issues like cracks, fading, and detached veneer in addition to a myriad of problems with the movement.

Regulating your Mechanical Clock

Regulating a clock often means making incremental changes to the length of the pendulum by means of a rate adjustment screw located at the end of the pendulum, or as in the case of a French clock pendulum (above) a rating screw inside the bob. Turning the rating screw clockwise shortens the pendulum (faster) and counterclockwise lengthens (slower) it.

Usually, one full turn of the screw means adding or subtracting a minute per week. To simplify the process some clocks have a rate adjustment arbour on the dial, typically at the 12 o’clock position. That way you do not have to open the access door at the back of the clock to adjust the rating nut on the pendulum.

If you have a double-ended key, the smaller end is used for the rate adjustment arbour. The “S” (slow) and “F” (fast) settings correspond to adjusting the clock’s speed—slowing it down or speeding it up. Clocks may have either one of these adjustments, but sometimes both (adjustable pendulum and rate adjustment arbor), as on this French shelf clock.

Rate adjustment is a trial-and-error process and typically takes a week or longer. If you can adjust your mechanical clock within a minute or two per week you are doing well. You will gradually gain a feel for the kind of adjustment required to regulate your particular clock.

Clocks without pendulums are those that have lever escapements, floating balance escapements, or balance wheel escapements. Regulation is achieved by moving a lever from slow to fast (as indicated on a wheel for instance) or adjusting weights in one direction or another on the escape wheel. There are specific directions on how to this and it is best to consult the instruction manual on your clock or search for resources online.

Mainspring Power and Regulation

When winding a spring-driven clock you are winding a sturdy coiled metal spring. The mainspring is an energy storage system or a power source. When you turn the key the winding gets tighter until you cannot turn the key any further. This stored energy (or potential energy) is now ready to be released but because a clock has reduction gears and an escapement (method for energy to escape) the energy is designed to be released at a steady and controlled rate. The purpose of the gear train is to convert the slow rotation of the main wheel into the faster rotation needed to tell the time. Each wheel in the train turns faster than the previous one.

A spring-driven clock tends to release most of its energy at the beginning of a cycle and releases less energy towards the end of it’s winding cycle which is typically an 8-day period. Most clocks will run longer than eight days but will lose more time as the spring supplies less power.

Regulating some spring-driven clocks can be challenging due to the way they release their power, though this can vary depending on the clockmaker. If your vintage or antique spring-driven mantel or wall clock is accurate to within 1-2 minutes per week, it’s performing quite well.

My Sessions time and strike tambour-style clock typically runs about one minute fast at the start of the week and around one minute slow by the end of the week. This is normal.

On the other hand, weight-driven clocks are more accurate since they release power at a constant rate through the winding cycle. Weight-driven clocks are generally more reliable timekeepers and are easier to regulate.

Neglect, friction, and environmental factors play a significant role in a clock’s ability to keep accurate time. By ensuring proper maintenance, placing your clock in a location free from heat and humidity, and regularly checking for adequate lubrication, you can extend its lifespan, maintain its value, and enjoy dependable performance for years to come.

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

This is more practical info than I’ve found anywhere else.

LikeLike

I try to help as much as I can.

Ron

LikeLike