Smiths Enfield mantel clocks are highly regarded by beginning clock collectors due to their popularity, abundance, and durable movements. For amateur clock repairers, they offer relatively few challenges.

I acquired my Smiths Enfield time-and-strike clock in 2013 from a young clock tinkerer in Dartmouth, Nova Scotia, but it was never a reliable runner. It would only run for a few minutes before stopping. Eventually, the clock was set aside and left in a corner of my shop.

While not an especially attractive clock it embodies the utilitarian design typical of post-war English clocks from the late 1940s and early 1950s.

After several months and armed with new knowledge of clock repair, it was time to take a second look.

About Smiths Enfield

The Enfield Clock Company (London) Ltd. was established in 1929, with its first clocks sold in 1932.

The company utilized modern assembly line techniques to manufacture and assemble its clock movements, inspired by the American system of automated factories. Initially, clocks were sold wholesale and for export, with the movements supplied to shops that would then assemble the cases themselves. Enfield took pride in producing “British-made” clocks. However, in 1933, facing difficulties competing on price, the company was sold to Smiths Industries, which led to the name change to “Smiths Enfield”.

In 1935-1936, they introduced a striking 14-day clock in a Jacobean Oak case, which helped solidify the company’s position in the market. With the outbreak of war in 1939, the factory shifted to wartime production. While clock production continued, material shortages became a significant challenge.

After the war, American machines were allowed to be kept and production of the 53mm movement re-commenced. Production was later moved to the Smiths factory at Cricklewood and then later to their Welsh factory in about 1955. Under Smith Industries the production line was changed to watches. Ultimately all clock production was phased out and the company closed shortly thereafter.

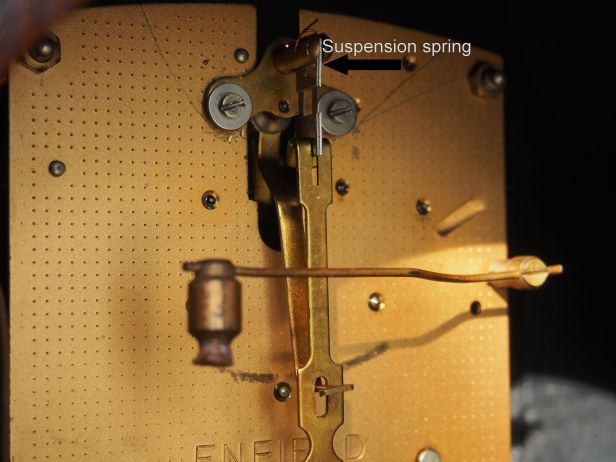

A New Suspension Spring?

I serviced the clock in 2015, and it needed bushing work. Since the wear wasn’t severe, I thought I could delay it for another two years. However, the clock has not been running since then. At the time, I knew little about the purpose and function of a suspension spring, and since I assumed the one that came with the clock was correct, I thought there must be another issue causing the clock to run poorly.

It’s time to revisit the suspension spring to determine if that’s the issue.

Over the past four years, I have accumulated an assortment of suspension springs and, through trial and error, found one that is either correct for the movement or very close.

The suspension spring has a mounting hole on one end and a small T-bar on the other where the pendulum hangs. I replaced the old spring with a shorter, more flexible one. As a result, the clock started running. In the first week, it lost about five minutes, but after making minor adjustments to the pendulum length, the timekeeping improved with each change.

The takeaway from this is that the correct suspension spring is crucial to whether a clock runs, and it should be considered as one of the potential reasons when a clock is not working.

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

I have a similar issue with a clock with a like movement and you have sent me in a direction that I should have picked up on.Thanks,

Ed

LikeLike

Well, it took me a while to get there but it is running like a top and completing the full 8-day cycle.

Ron

LikeLike