In 2016, my wife gifted me a two-weight Gustav Becker regulator wall clock. It was a much-appreciated gift, and I spent many hours restoring it, as it had been sold as a “project clock.” The case certainly had its issues, but the most challenging problems lay in the movement itself.

At the time, I was not familiar with Gustav Becker movements, and it did not immediately occur to me that several key components were missing—almost as if a previous owner had harvested parts for another clock. One example was the absence of the star wheel. I contacted the seller, who kindly sent several replacement parts, including a star wheel. Unfortunately, it did not fit.

It was then that I learned Gustav Becker had made design changes to these movements over time, meaning that not all parts are interchangeable. It appears the star wheel was sourced from a later model.

That led me to source a replacement movement, which I was able to obtain through an eBay seller. The price was more reasonable than I expected, and the movement arrived intact. Initially, I thought I could harvest parts from it for the original movement; however, as I had already learned with the star wheel, some parts did not fit.

Using replacement parts in antique clocks presents a number of challenges beyond simple fit and function. Even when parts appear correct, subtle differences in design, dimensions, or period manufacturing can affect performance and reliability.

From a collector’s perspective, non-original or mismatched components may also impact a clock’s historical authenticity and, in some cases, its market value. For the restorer, this often requires balancing mechanical integrity and long-term usability against the desire to preserve originality as much as possible. Of course, to the casual observer, the clock appears original.

I ultimately decided to abandon the 1902 movement and use the 1918 P27 one instead. The 1918 movement has been running flawlessly for the past 9 plus year and that is why the issue I am describing in this post surprises me. Or, should it!

Most people would be inclined to dismiss the problem by simply restarting the clock, which is what I initially did, but several hours later, the clock stopped again.

The problem is this: the warning lever, which drops into the warning wheel to stop the strike in warning, seems to freeze intermittently. For proper function, the strike release lever is lifted by the minute wheel pin to release the warning lever. I believe the issue occurs at the stop-wheel pin, where it appears to bind or stick. When I manually lift the warning lever to release the stop wheel, the strike train will run for a while, then stick again.

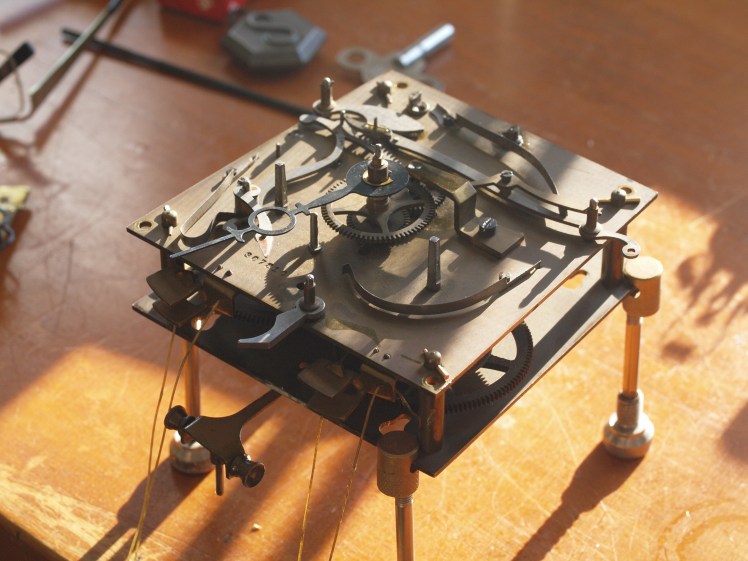

When I disassembled the movement, I checked for broken or bent teeth, bent pins, and the general condition of the pivots. Everything appeared to look good. However, given that the clock has been running for a long period, the issue now seems more consistent with wear than with a sudden component failure.

One issue could be that excess endshake may be allowing the stop wheel to move fore and aft, altering how the stop pin engages the warning lever. Additionally, many weight-driven warning levers rely purely on gravity for return; any increase in friction can cause the lever to hesitate or become caught on the edge of the pin. For these reasons, I believe this is a general wear issue rather than a broken or failed component.

By way of comparison, the average American-made movement produced a century ago could often continue to run reasonably well despite significant wear, whereas German movements—built with tiny pivots and very close tolerances—tend to be far more sensitive to wear, dirt, and minor loss of power. This difference should perhaps not be unexpected.

The movement is currently disassembled and, after many years of service, likely requires bushing work.

In short, the symptoms point to accumulated wear rather than a specific failed part. The movement will therefore receive full bushing work where needed, followed by a thorough cleaning, reassembly, and testing on the stand. Only once the strike operates consistently and reliably under full weight will the movement be returned to the case.

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

Wow Ron, most peop

LikeLike