Among clock collectors and admirers, the Hamburg American Clock Company is a well-known German company. It is otherwise known as Hamburg Amerikanische Uhrenfabrik or HAU and in many parts of the world, it is simply known as HAC.

In this post, I will outline the procedures involved in servicing the movement of a HAC mantel clock produced circa 1925. It’s worth noting that HAC crafted clocks for international markets, and in the case of this particular clock, it spent a period in England after its initial manufacturing.

Disassembling the movement

After removing the clock hands and releasing the six screws that attach the movement to the front dial board the movement can be maneuvered carefully around the bronze rod gong without having to remove the gong itself.

Once out of its case, the first step is to remove the suspension spring and pendulum leader. A taper pin secures the spring onto the suspension post.

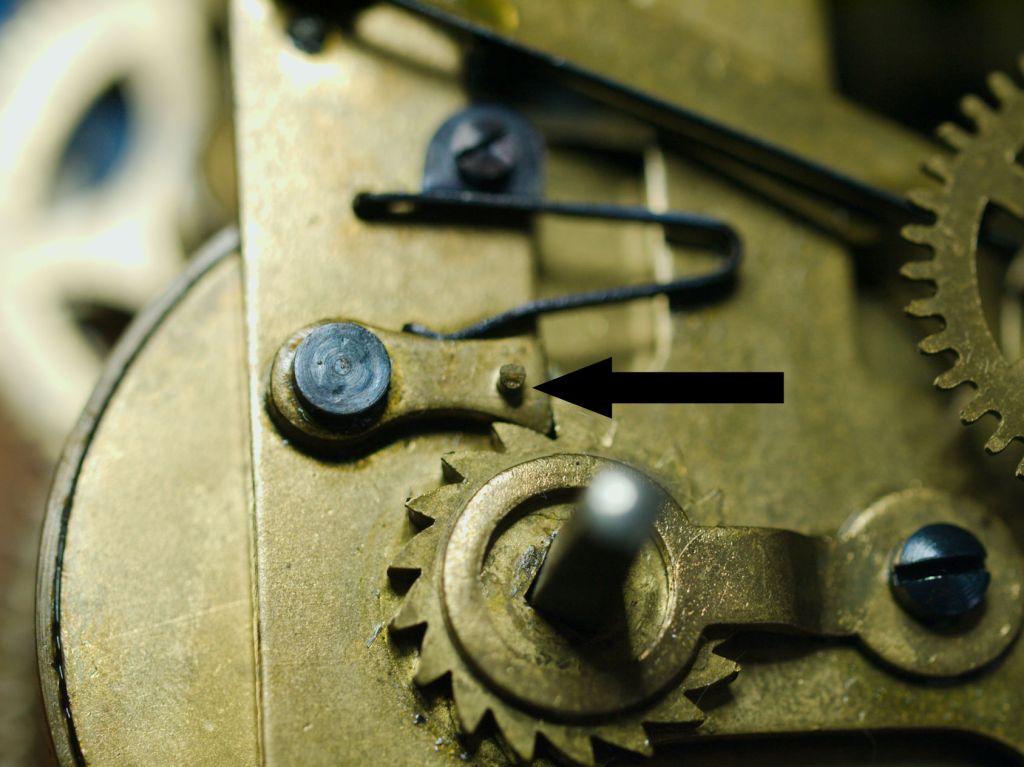

Next, safely let down the mainsprings using a letdown tool. On this movement, and I have not seen it elsewhere, there is a small pin on each rachet. Once the letdown tool is placed in the arbour, it is a simple matter of pushing the pin on the click with a small screwdriver and allowing the rachet to run freely, under control, of course.

At this point, the two exterior wheels, both rachets with their retainers and the click springs can be removed as well as the “V” shaped stop lever.

On the front of the movement, two screws hold the pallet arbour plate, and with it comes the crutch. Note the position of the small pallet arbour plate for future reference. This is also a good time to remove the hammer from its arbour but the plates can be separated with the hammer still attached.

At this stage release the 4 nuts holding the movement and the back plate can be removed. There are two springs which look like stiff wire, one is for the count lever and the other for the hammer. Do not break these springs and be careful handling the plate once it is separated. The wire springs can be repaired if they break but it adds more work to servicing.

Once the plate is lifted from the movement, the wheels and levers can be removed. Strike and time side wheels are then separated into containers. I like working from the top down and carefully removing each wheel one at a time. The centre cannon is the last wheel to be removed. The half-hour cam, a star wheel with two points, is on a tube which can be pulled off the arbour and the centre wheel easily lifts out. Once the centre cannon is removed the mainspring barrels can be extracted and put aside for servicing.

Assessing wear

Identifying whether a movement has undergone previous work can be challenging, but scratch marks around pivot holes typically suggest past work. An unmistakable sign of prior servicing is the presence of punch marks, as observed around the mainspring barrel on the time side. The aggressive punching suggests that the arbour hole was enlarged considerably. However, the arbour’s fit through the barrel appears sufficiently tight, indicating no immediate concern.

While it’s not approved today, punching pivot holes was a common practice in the past.

The movement is relatively clean but over-oiled the result of simply lubricating the clock over the years without actually checking to see if it required new oil.

There are very few issues with the movement with a potential need for two new bushings on the strike side and just one on the time side.

Cleaning the movement parts

Cleaning a clock movement’s parts is a fundamental step in the maintenance and restoration process. It not only improves the immediate performance of the clock but also contributes to its long-term durability and accuracy.

Cleaning a mechanical movement’s parts before reassembling a clock movement is crucial for several reasons, to remove dirt and debris, prevent wear and damage, optimize performance identify and any perfomance issues. Cleaning is often accompanied by the application of fresh lubrication to key components. Lubrication reduces friction between moving parts, minimizing wear and ensuring smoother operation. This step is vital for maintaining the health of the movement.

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

Need info on 8 day Anniversary clock. Main cannon shaft is broken. Does the shaft all in one length or is it pieces I have to fabricate.

LikeLike

The gear or wheel is friction fit on the shaft so, in order to fashion a new shaft the tolerance would have to be tight.

LikeLike

Is the main shaft in 3 sections or one piece

LikeLike

If there are any dissimilar metals along the shaft, then it may be 2 or three.

LikeLike

Hello Ron, the last of your post I received was 24. March 2024. I had a very bad PC crash and have to rescue what I or my PC guy can manage. Where can I find the missing posts please?

I had objected in the beginning to the ads, but have long ago accepted them, seeing you give excellent information to a community of clock lovers / repairers etc. As a professional (all be it semi-retired) clockmaker I can see a lot of merit in your instructions to amateurs. For me the most valuable matters are the histories of clockmakers/factories. Here in SA we mostly deal only with the cheaper type of the USA productions. That’s because the importers went for the most reasonable makes and models.

Best regards, Thomas

thomas@niemo.co.za

LikeLike

Hi Thomas and thanks for the kind words. Sorry for the delayed response. My wife and I recently got back from the UK. During our trip, an important family issue came up, causing the blog to take a back seat. There is a search box on the front page of the block. Simply insert a key word and you should find what you need.

LikeLike