A Chinese-made vintage Daniel Dakota time and strike 31-day wall clock purchase will not set you back a lot of money. These clocks are everywhere and they were made in the many thousands. I would bet that 99% of them have never seen the inside of a clock repair shop. They have cheap movements which seem to defy death, they last forever or end up unceremoniously thrown in the trash bin.

The clock, which I bought in a junk shop some years ago, was gifted to a family member but it has been returned to me, not working; the boomerang effect. The family member has no desire to have it returned to them and I do not have a problem with that. Instead, I gifted them a much more refined German Schatz chiming bracket clock.

Chinese-made clocks have a design lifespan of about 20-25 years. They were never intended to be passed down as family heirlooms

On online for-sale sites, these things are ubiquitous. Sellers believe these vintage clocks are worth something judging by the silly asking prices on online for-sale sites. On any given day, you will find dozens on eBay ranging in price from $30 to $160 and they will find new homes for the unsuspecting. Most are quartz but there is the odd mechanical one.

This is a Chinese-made clock. Most Chinese (or Korean) clocks of the 1960s have inexpensively manufactured movements with thin plates, thin stamped wheels, plenty of clips and washers, long dangerous mainsprings, and have every component made with cost-saving in mind. During the 1960s and 70s, there was a strong demand for mechanical clocks and Chinese manufacturers stepped in to fill it. These are clocks made for the masses and were good sellers in their day but have a design lifespan of about 20-25 years. They are tough but were never intended to be passed down as family heirlooms.

The 31-day run times mean that the mainsprings are very powerful and if they let go they are sure to do some damage not only to the moving parts inside but to anyone handling them. It is one reason why many in the clock repair business stay away from them.

However, they are surprisingly strong runners and will provide service for years while quite worn. If they stop, the cost of repair is far more than they are worth. When they stop, quartz movements often replace mechanical movements or the clock is simply thrown out.

If you have worked on an English or German time and strike movement most everything will be familiar to you in terms of wheel placement since the Chinese copied existing designs. Some components like the fly and the star wheel are designed differently but their function is the same, of course.

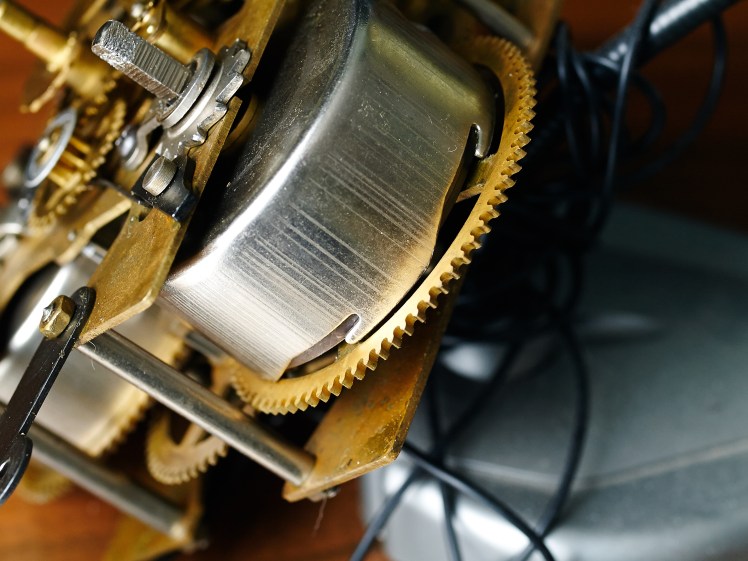

What is very different are the dangerous twist-on mainspring barrels housing long, powerful mainsprings which are not fun to work on.

Why service the movement

Not surprisingly, these clocks can easily be brought back to life if there are no serious issues.

During the course of disassembling a typical Daniel Dakota movement, if I discovered something seriously amiss such as broken teeth, seriously bent arbours/broken pivots or broken mainsprings, I would stop immediately. There is no point in expending time, energy and expense on a throw-away movement. There is no source of parts for these things and if the type of repair offsets its value, there is no point. If everything looks relatively good, servicing makes sense and the only cost would be time and perhaps a bushing or two.

Let’s look at this movement

This came to me as a non-working movement. The movement is very dirty, the plates are tarnished, but the wheels run relatively free, the gear teeth have little wear, the pivot holes look good, the mainsprings are strong and none of the components appear to be damaged.

A deeper dive revealed some interesting issues. Once I took the movement apart I discovered two key trouble spots, a bent escape wheel pivot, and a bent flywheel pivot. It is a wonder that it even ran but no surprise that it finally stopped.

Bent pivots can be repaired. All the lantern pinions are in excellent condition, with no worn wheel teeth and the mainsprings are strong. There were punch marks around several pivot holes, likely done while the movement was assembled.

Repairing a bent pivot and cleaning the movement

Care must be taken when addressing bent pivots. If the pivots break while attempting to straighten them there is not much point in going any further on a cheap clock unless practice in repivoting is the goal.

A lathe comes in handy but a portable electric drill will do. Place the wheel into the jaws and hand spin it to check the direction to bend it. Using a staking tool rather than a hammer means you can apply very little pressure, checking progress with each gentle bit of persuasion. It is soft steel and will take a little bending but don’t get carried away.

Both the escape wheel and the fly pivots were straightened. All other pivots were inspected and everything looked good. Now on to cleaning the movement in the ultrasonic machine.

The parts were dried and cleaned but the ultrasonic machine did little to reduce the tarnish on the plates. The movement will function quite well without shiny plates, purely a matter of aesthetics.

Once the plates were cleaned and pegged out I could see very little wear. The only enlarged pivot hole is the second wheel time-side, backplate which is not surprising since there is a heavy load on this wheel from the mainspring. This required a 1.50mm bushing with an OD of 3.50mm.

Reassembly

Seeing no other bushings holes requiring remediation, the movement is re-assembled.

Once the bottom nuts for the barrels and second wheel and cannon wheel are put on and tightened, the time side wheels are secured and the corner nut is next. Once that section of the movement is in place, the strike side wheels are coaxed into position. This is where a pivot locator is your best friend. The pivots are thicker than those found on a typical German movement but can still be bent through rough handling.

Last, are the levers, snail, rack, and hour wheel on the outside of the front plate.

Final thoughts

Was the exercise worth it? Of course! I have worked on dozens of similar (English, German) types of time and strike movements I always find something that adds to my learning. These movements are easy to work on, are surprisingly strong runners when in good order and presented no issues during servicing.

In total, it cost me my time plus one bushing. Would I send this off to a shop for repair? Of course not! Why pay $250 or more to repair a clock that is worth almost nothing on a good day but for sentimental reasons it may be important for some.

Why fix it? To sell it, of course! I’ve had it a few years and enjoyed it, a family member has had it for a while and enjoyed it and now it is time to pass it on.

Wow, I can’t believe how a wall clock could be so complex and complicated. It takes professionals to really fix it. I usually just buy a new clock from https://orchidranchfurniture.com/collections/all-wall-clocks each time the old ones give out. I guess I can have clock experts fix some old ones but the shop always brings in freshly designed clocks so I end up buying new ones!

LikeLike

But, will your new one run 100 years or more and sound as good as the day it was made? I doubt it.

LikeLike