As a clock repairer, there are several compelling reasons to keep the original mainsprings if they are still in good condition.

Keeping the original mainsprings ensures that the clock remains as close to its original condition as possible. Collectors and enthusiasts often value clocks with original parts, as they maintain the authenticity and historical significance of the clock.

Many older mainsprings were made with higher-quality steel and manufacturing techniques and modern replacements may not be of the same quality. Original springs, if well-preserved, may outperform modern equivalents in terms of durability and performance.

Consider the original design of the movement and how it is powered. The original mainspring is designed specifically for the clock’s movement, ensuring the proper balance of power delivery and running time. Replacements, even when sized correctly, may not deliver power consistently due to slight variations in material and design.

Modern mainsprings can sometimes deliver too much power, especially in delicate or vintage movements, leading to accelerated wear or damage to gears and pivots. Original springs are often “seasoned,” meaning they’ve been conditioned by years of use and may be gentler on the movement. Even replacements that have the same dimensions as the original are overpowered. Recommended replacement springs might overload the movement and lead to wear issues sooner rather than later.

Laurie Penman, who authors a regular feature in Clocks Magazine, stresses the importance of considering replacement springs in the September 2024 issue, stating “it bears repeating that if you fit a spring that approximates to the original nineteenth century the movement will be overloaded”.1

If the original mainspring is functional, reusing it can save the cost of purchasing a replacement. In fact, finding an exact replacement for some older or rare clocks can be very challenging for the repairer.

That said, we certainly do not need to send more items to landfill sites. Reusing parts when possible reduces waste and the environmental impact of manufacturing new components.

Inspect the mainsprings during every servicing

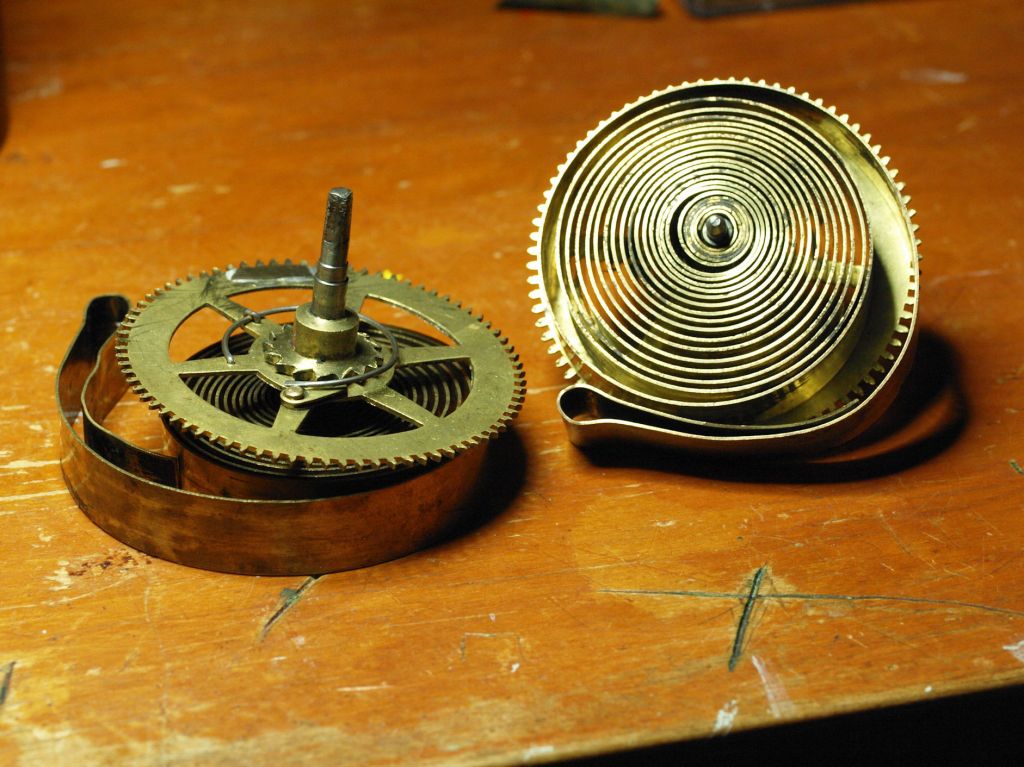

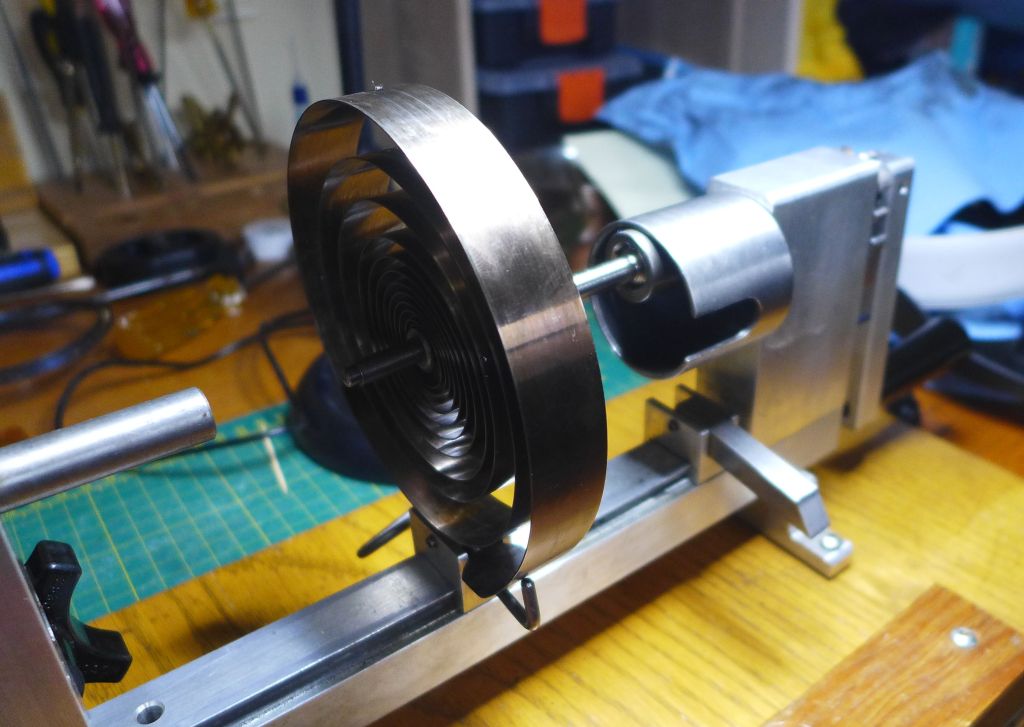

Part of servicing a clock movement includes inspecting and cleaning the mainsprings. While open mainsprings are easier to inspect and work with, some repairers may be tempted to skip cleaning those encased in barrels. It’s important to learn how to open mainspring barrels for proper maintenance.

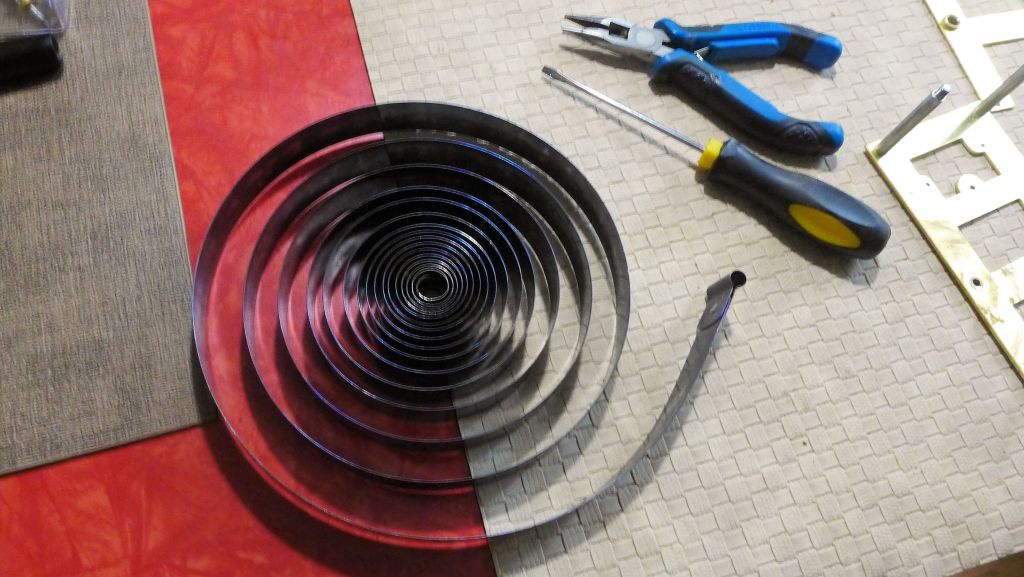

Over time, the mainspring(s) can accumulate old oil, dirt, rust, and debris, which can impede its smooth operation. Removing the mainspring from the barrel or open springs from a movement allows for proper cleaning and lubrication, ensuring the clock runs efficiently.

Removing the spring also allows you to apply fresh mainspring oil evenly along the entire length of the spring. But that is not the only reason.

When Should You Replace the Mainsprings?

Removing the mainspring allows you to thoroughly inspect it for any signs of wear, fatigue, or damage that might require replacement. If the spring is in good condition but the hook end is cracked, it can be reused by cutting the spring and fashioning a new hook end. This will make the spring slightly shorter.

However, after a thorough cleaning, the movement will run more efficiently and require less power to run through its designed cycle, be it a day or a week, two weeks, and so, there may be little to no effect from a shortened mainspring. That said, the task of repairing a mainspring is best suited for an experienced clockmaker.

The most straightforward solution for the novice is simply to replace the spring.

As a clock repairer, I rarely replace a mainspring. Even if a mainspring appears “set,” it often still has functionality. The important step is to return the spring to the movement and test it to ensure it meets the required standard by completing its designed cycle. If there is a significant loss, a running time of 2-3 days for an 8-day clock, and if there are no other obvious issues the mainspring must be replaced.

For some, ensuring a clock runs while preserving its original parts might take priority, even if the original mainspring cannot power the clock through its designed cycle. It is therefore essential to balance preservation with functionality.

By carefully evaluating the mainspring’s condition and the specific needs of the movement, you can make an informed decision that respects both the clock’s history and its mechanical performance.

- Clocks magazine, September edition ↩︎

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

Good morning Ron,

I always examine a main spring closely not only for wear but for an inscription and date inscribed by a fellow horologist. My local clock repair shop horologist here in Peterborough was taught the trade in England. He advised me they the act of inscribing a customers clock following a repair or cleaning is shunned upon in England so horologists there would often mark the main spring knowing that the average person and or clock owner would never see deep inside a mainspring coil. So if you ever come across an inscribed main spring you’ll know it was repaired or cleaned by someone either in England or taught in England

LikeLike

Good morning to you. A very good point. Customs vary from region to region. What might be acceptable here may not be regarded as a good practice elsewhere.

LikeLike