Among clock collectors and admirers, the Hamburg American Clock Company is a well-known German company. It is otherwise known as Hamburg Amerikanische Uhrenfabrik or HAU and in many parts of the world, it is simply known as HAC.

About the Company

The company was formed in Germany in 1873 by Paul Landenberger and Phillipp Lang. Originally called Landenberger and Lang, it became the Hamburg Amerikanische Uhrenfabrik in 1891. The company was very active from 1885 onward, became a cooperative in the mid-1920s, and eventually merged with Junghans, one of the world’s largest clock companies, in 1930.

Original investors insisted that “American” be in the company name but “American” also refers to the manufacturing system adopted from America. The name of the company adds confusion to the novice repair person who might assume that what they are working on is an American-made clock.

HAU adopted the cross arrows as their trademark in 1892, and it became synonymous with the brand.

In 1925, a few years before its merger with Junghans, the company had a workforce of 2,200 individuals. Junghans remains a successful and thriving company today, specializing in high-end watches.

Condition of Case and Remarks

The case is in very good condition but was missing the crown when I purchased the clock in 2021. Since then, I have sourced a crown, and based on the research I have conducted online, it appears to be the correct “topper” for this clock.

The dial face is in good condition and shows some wear but not like the heavily worn dials I have seen on similar HAC clocks.

A commemorative brass plaque at the base reads: “The Rev. J. H. Cox Chyndale Wes’ Church Aug. 1926.” I assume this church is in the UK, but my online search yielded no information about this person. However, this inscription helps date the clock to no later than 1926. It is possible the clock may have been on a retailer’s shelf for several months or even up to a year or more before that date.

The Movement | Notes and First Steps in Servicing

In typical HAC fashion, the movement is robust and compact and it is a countwheel strike. The spring barrels are capped in the usual manner but feature four holes that make the mainspring visible. Earlier HAC movements had fully enclosed barrels—perhaps a cost-saving measure to use less brass! Otherwise, everything else is standard HAC.

Four nuts hold the movement plates. Once separated I removed the parts and divided the time and strike wheels.

Take careful note of two wires protruding from the rear plate. They act as tension springs, one for the strike hammer and on the opposite side of the movement, another for the lifting lever. These can easily break off, so handle the movement with care.

After disassembling the movement, it was cleaned in an ultrasonic cleaner. My aim wasn’t to achieve the shiniest brass possible but to ensure the brass and steel parts were thoroughly cleaned. There was some rust on two movement posts, which I removed using emery cloth. All parts were thoroughly dried.

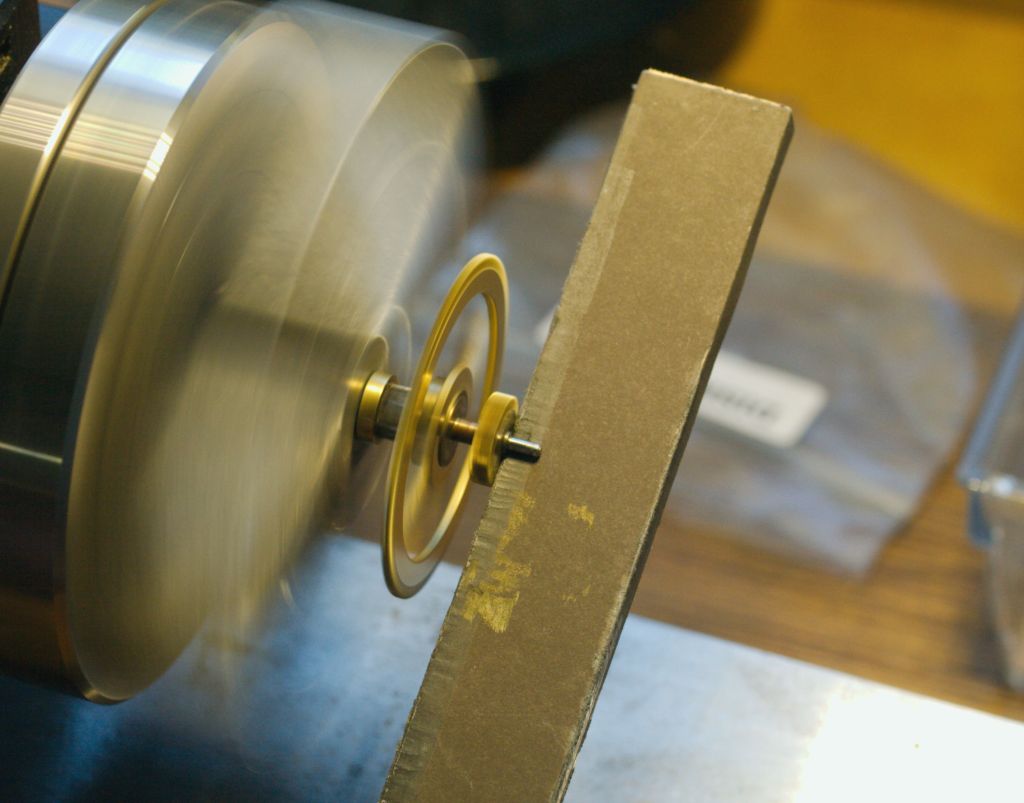

The process may vary, but I moved on to polishing the pivots next. Since pivots are quite delicate, especially the fly, it’s important to handle them with care. Avoid applying excessive pressure on the pivot when using a metal lathe for polishing.

I know some repairers prefer to avoid servicing mainsprings due to the difficulty of extracting them. However, it is essential to do so for several reasons. Clean and lubricated mainsprings ensure consistent power, enhancing the clock’s accuracy and performance. Additionally, it provides an opportunity to inspect for defects, cracks, and rust and replace them if necessary.

Once cleaned and lubricated, the springs are returned to their barrels using a spring winder such as the one made by Olie Baker.

Since brass is softer than steel pivots one should expect some wear on the bushing holes. There are parts of a clock movement that exhibit more wear than other parts.

For instance, the wheels that spin the fastest are often the areas that show the most bushing wear but wear can show up in other places as well. I noticed punch marks on the cap side of each mainspring barrel. While punching around any bushing hole is generally poor practice, it appears this was done at some point in the clock’s history and can’t be reversed. Nonetheless, the repair seems to have held up well.

Next Steps

After inspecting and cleaning the movement, and polishing the pivots, the next step is to install new bushings. In my next article, I will focus on this process, along with the reassembly and testing of the movement.

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

Ron – hi

Fascinating story. You’ve probably been here, but a quick Google took me to this nicely put-together site about the Wesleyan Chapel.

Sadly nothing there for the period around 1926 when the clock was gifted, but I imagine there are local historians on the site who might provide more information.

I too have struggled tracing folks named on clock plaques. Here’s an example:

https://www.theclock-shop.co.uk/clocks/pick-of-the-clocks-more-clock-of-the-picks/

Hugh

Sent from Samsung Mobile on O2

Sent from Outlook for Androidhttps://aka.ms/AAb9ysg

LikeLike

Thanks Hugh. I left a comment on the article, and I’m curious to see what kind of response I’ll get.

LikeLike

Good morning Ron,

into have a couple HAC and Jungens clocks in my collection. On the topic of servicing the main spring I always watch for any inscribing on the mainspring. Many horologists adopt the belief that it is unethical to mark any customers clock (a common practice by many moderne day horology hobbyists) but knowing that the clock owner will rarely ever see the inside of a main spring it was a common practice by horologists in England to inscribe the main spring.

As for the punch marks on the bushing holes, I see this on many if not most clocks that I’ve encountered. It seems to be a common practice to reduce the inside diameter of the bushing then ream them back to the desired diameter.

I’ll send you a pic of my favorite HAC kitchen clock. Which has proved to be a challenge to keep working but it is currently ticking away.

LikeLike

I have the picture, thanks. It’s cute! I notice that it has a conventional pendulum, much preferred over those with a balance escapement. I make a practice not to erase the sins of past repairers and if the fix has stood the test of time, I leave it as it is.

LikeLike