Is your mechanical clock experiencing issues such as intermittent stopping or simply not running at all? This might be due to several issues with the movement, one of which could be pivot wear.

This is a two-part series. In Part I, I will explain why it is necessary to bush a clock movement, and in Part II, I will describe my method for bushing.

What are pivots?

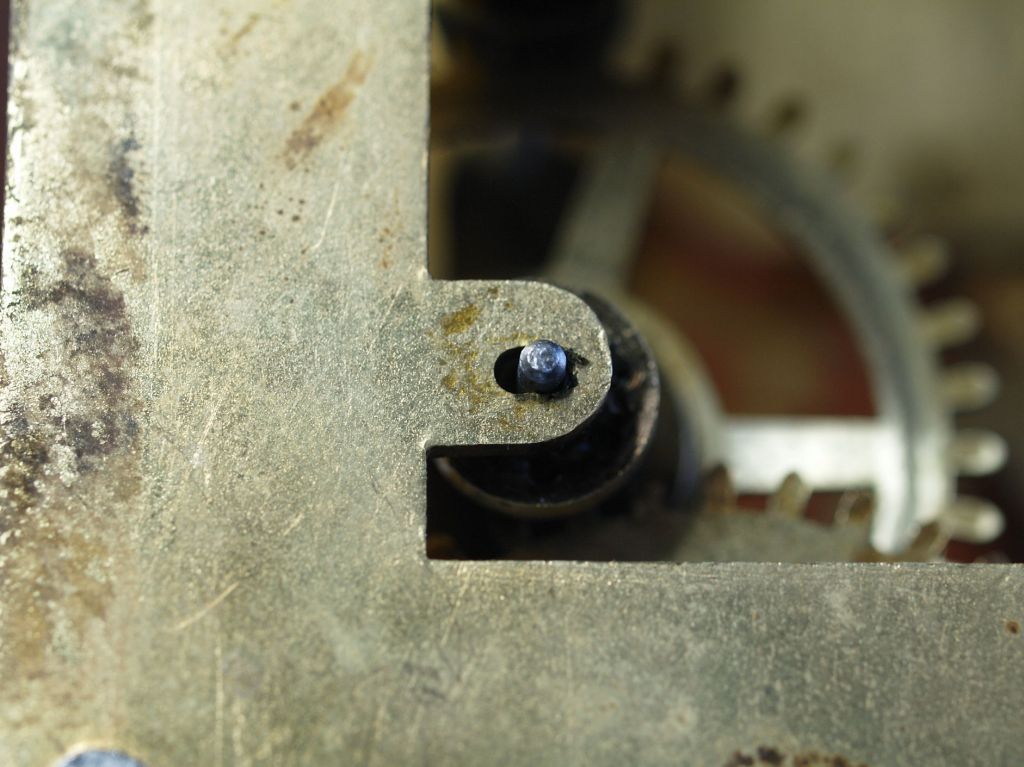

Pivots are the ends of the axles, known as “arbours” in horology, that rotate in small holes drilled into the clock plates as the clock runs. They are the turned-down ends of the arbour. These, along with the holes they rotate in, can wear down over time causing enlarged holes that will contribute to poor running or stopping. The pivot hole must be perfectly round, and the pivots need a mirror-like polish to minimize friction within the train of gears. To protect the surfaces and reduce friction, approved clock oil acts as a barrier between the pivot and the pivot hole.

Worn pivots or pivot holes can cause the wheel to drift away from the pinion, eventually stopping the clock as the gears fail to mesh properly. Clocks in need of bushings may run erratically or stop altogether.

Oiling a dirty or worn movement

If a clock movement isn’t routinely serviced (cleaned and oiled), the plates of the movement will experience wear at the pivot points. Applying new oil over old oil can free abrasive dirt and provide a temporary solution but accelerate wear on the steel pivot and brass bushing holes because the contaminated oil acts like a grinding paste.

Worn pivots are often found in clocks repeatedly oiled without proper cleaning. Proper servicing requires disassembling the movement, cleaning the parts, addressing wear issues, reassembling, and testing.

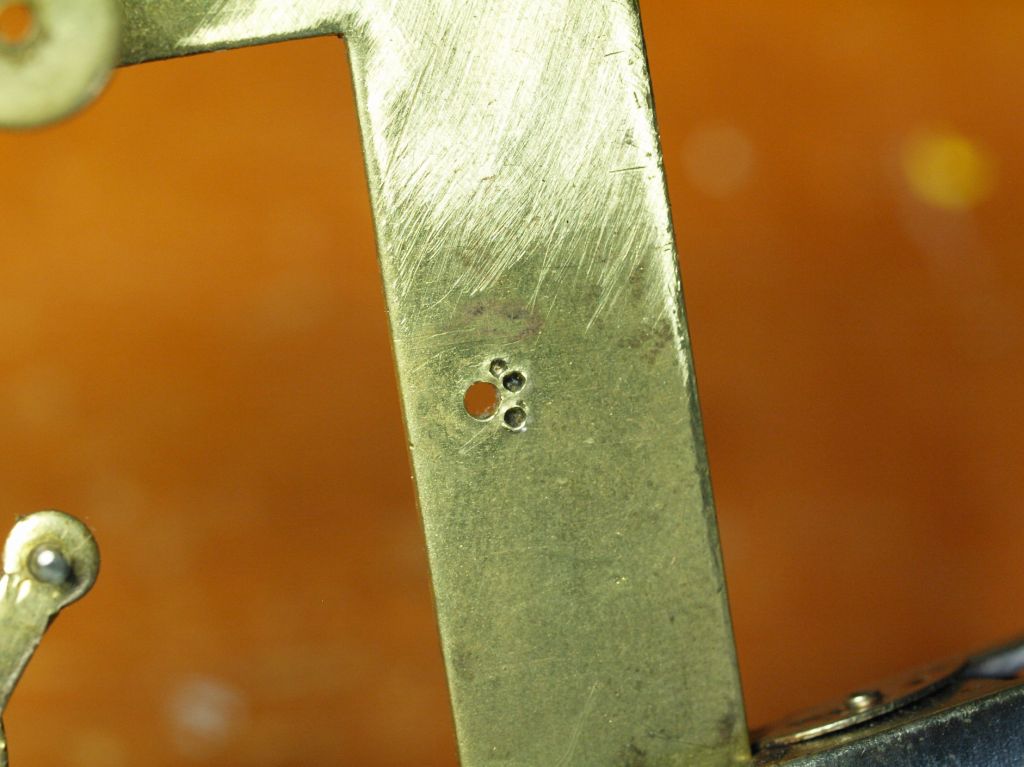

Punch marks

From time to time, there is evidence of punch marks located around the pivot hole which is an attempt to close worn pivot holes. While a common practice in the past, this is no longer considered an acceptable repair practice.

Pivots need periodic cleaning and polishing to turn freely in the clock movement plate hole. Worn pivot holes are easy to identify as they appear oval-shaped rather than round.

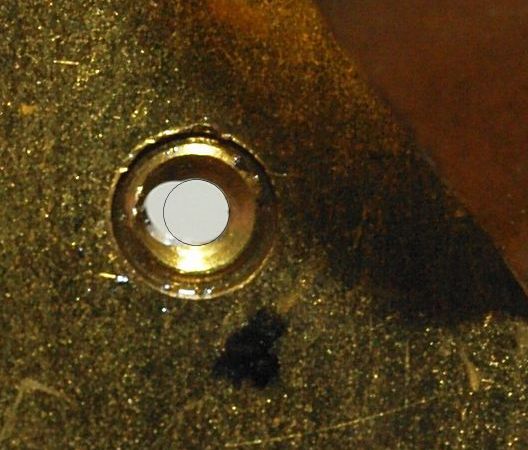

What is bushing?

“Bushing” is the process of replacing worn brass around the pivot so that the hole is round again. A new hole is drilled into the plate, and a new, appropriately sized bushing is pressed into place using a bushing machine like the Bergeon Bushing Machine.

Some clockmakers prefer to hand-bush using reamers and smoothing broaches, producing satisfactory results, though a machine simplifies the task and is more accurate.

Severely worn steel pivots must be replaced with new ones, a process called re-pivoting. This involves using a watch or clock lathe to drill into the end of the wheel arbor to install a new pivot made from pivot wire.

Minor wear is expected over a clock’s life and can be managed with careful filing, polishing, and burnishing.

In summary, bushing is an integral part of movement servicing. Well-maintained clocks may show minimal wear and may not require new bushings, while others, due to neglect or improper servicing, may require many bushings.

Proper pivot and bushing work can extend a clock movement’s lifespan, ensuring reliable operation for years.

In Part II of this two-part series, I will describe my method for bushing a clock movement

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

I only discovered the reason clocks stopped was pivot wear this year. The owner of the shop near me is slowing down and will probably not be in business when my clocks need his expertise later. This will mean my clocks will eventually fail. This has caused me to not make any further purchases. Thank you for your information.

LikeLike

It’s understandable to feel apprehensive about the future maintenance of your clocks, especially with the local expert winding down his business. There are still options available to ensure your clocks remain in good working condition. There are many reputable clock repair specialists and horologists who can provide excellent service, even if they are not in your immediate area and there are resources and communities online where you can seek advice and support for maintaining your clocks.

Don’t let this discourage you from enjoying your passion for clocks. With the right care and maintenance, your clocks can continue to bring you joy for many years to come.

Ron

LikeLike