Clock movements often require bushing for several reasons. Over time, the original brass bushings can wear out due to friction and other factors. When this occurs, the holes in the clock plates become enlarged and misshapen, resulting in a poor fit between the components that interact with each other. This wear and tear can lead to excessive play in the gears, causing the clock to run erratically or not at all.

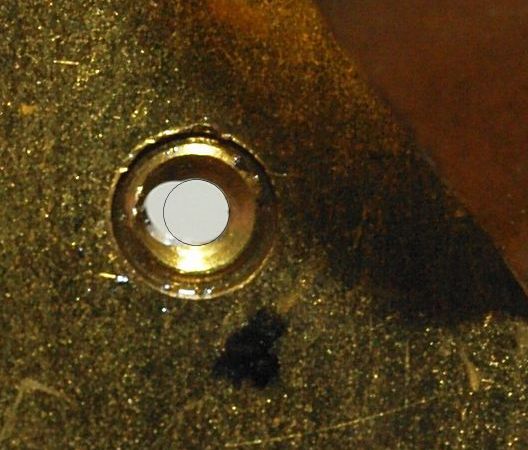

Bushing involves inserting new brass bushings into the worn-out holes of the clock plates. These bushings provide a precise and snug fit for the pivots, ensuring the gears move smoothly. Bushing prolongs a clock’s lifespan and maintains its accuracy over time.

This proactive approach to maintenance can help preserve the integrity of the clock movement and prevent more costly repairs in the future.

The smoothing broach – what it does and how it’s used

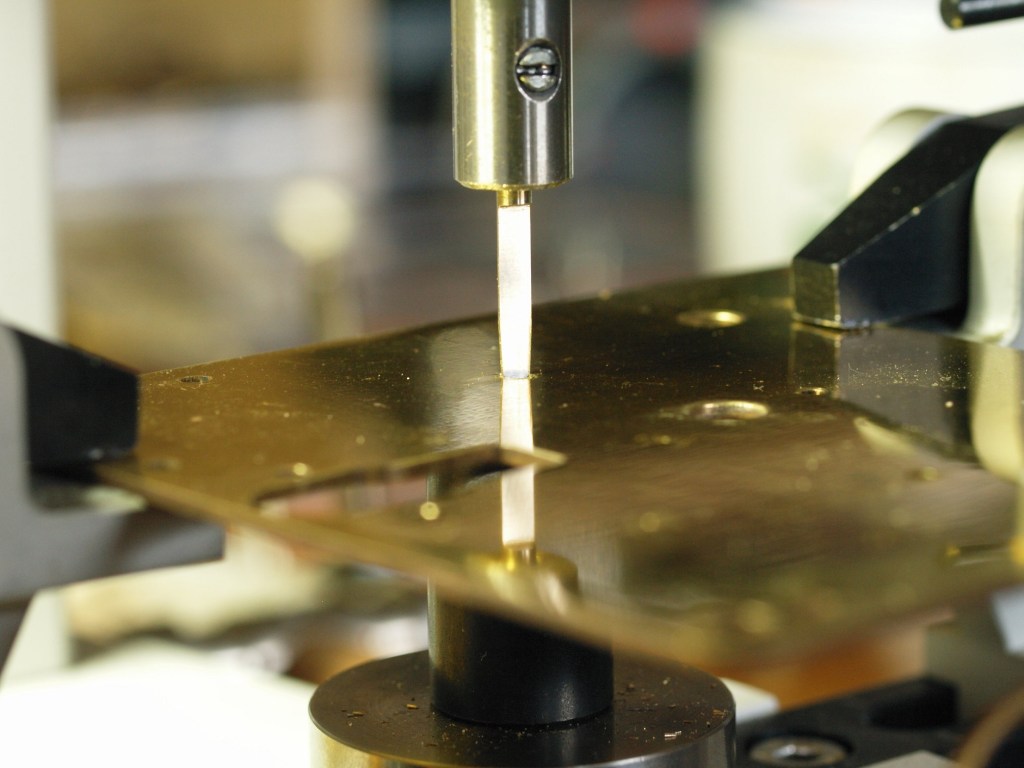

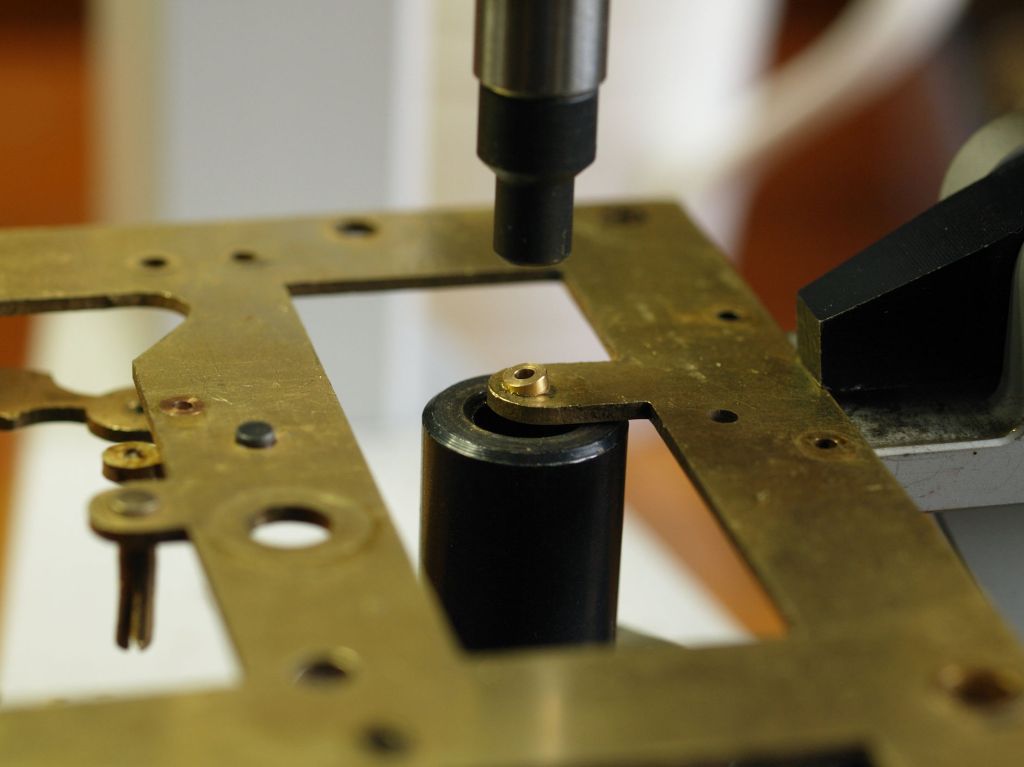

When bushing an antique clock movement, the bushing machine, such as the Bergeon 6200 bushing machine, enlarges the pivot holes using a cutter. This cutter is responsible for creating a hole large enough to accommodate a bushing of the appropriate size, which is then pressed or punched into the clock plate.

When choosing a bushing It is advisable to select a bushing that has a slightly smaller inside diameter for optimal performance. Once the bushing is installed, a cutting broach is employed to enlarge the hole just enough to ensure the smooth movement of the pivot.

A cutting broach typically resembles a slender, tapered metal rod with flutes or grooves along its length and is usually 5 sided. It is designed to remove material as it is rotated within a hole. The removal of the material enlarges the hole. The size of the cutting broach corresponds to the desired diameter of the hole being created or enlarged.

The final step is the smoothing process.

Smoothing broaches offer several advantages. Firstly, these broaches are designed to finish the holes in the clock plates, ensuring proper fitment of the bushings.

Smoothing broaches help to remove any remaining burrs, irregularities, or minor debris from the interior of the bushing holes, promoting the smoother operation of the gears and other components. This contributes to the overall performance and longevity of the clock.

Needless to say, smoothing broaches are specifically designed for clockmaking purposes, meaning they are engineered to withstand the demands of the job and provide consistent results when used time and time again. This reliability is essential when working on valuable and delicate antique timepieces. Investing in high-quality smoothing broaches is advisable to ensure the best results, particularly when working on valuable and delicate antique movements.

Smoothing broaches are available in various sizes, so it’s crucial to select the one that matches the inside diameter of the new bushing. Once the cutting broach has completed its task of creating a hole of the correct size, the smoothing broach takes over as a finishing tool. Carefully twist or rotate the smoothing broach while gently cleaning the hole, inserting it from the inside of the plate and then the outside to ensure the hole is cleaned thoroughly and evenly. After the broaching process, the last step in preparing the new bushing hole for the pivot involves cleaning the inside of the hole with a toothpick to eliminate any minute debris left from the smoothing process.

Overall, the use of smoothing broaches when bushing an antique clock movement ensures proper fitment, smooth operation, precision, and reliability, all of which are crucial for preserving the integrity and functionality of a clock movement.

Proper clock servicing requires a comprehensive arsenal of equipment, with smoothing broaches being just one essential component.

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

Would it be correct to say the failure of the bushing is the most common reasons antique clocks stopped working?

LikeLiked by 1 person

I would say that it among the most common reasons.

LikeLike

I have been watching many tutorials and reading a great deal with hopes of being able to perform hand-bushing on some of my clocks.

fascinating process!

LikeLike

I think whatever works is great. I am not a hand-bushing expert and prefer to leave it up to what I think is a very capable machine.

LikeLike