In this article, I will outline the reasons for opting to use an ultrasonic cleaner in clock repair, delve into how the unit operates, and provide recommendations for those contemplating the use of an ultrasonic cleaner in their clock workshop.

What is an ultrasonic cleaner?

An ultrasonic cleaner typically resembles a rectangular tank made of stainless steel. It features a hinged or removable lid for easy access to the interior. Inside the tank, there are transducers mounted on the bottom or sides, which emit high-frequency sound waves.

The tank also includes controls such as timers and temperature settings to regulate the cleaning process. Additionally, there may be a drainage spout or valve for convenient removal of the used cleaning solution. Depending on the model, ultrasonic cleaners can vary in size from small tabletop units to large industrial machines.

An ultrasonic cleaner is used for cleaning a wide array of objects. The high-frequency pressure (sound) waves create cavitation bubbles within a liquid, generating intense agitation. This agitation exerts significant forces on contaminants adhering to various substrates such as metals, plastics, glass, rubber, and ceramics. This process is able to penetrate blind holes, cracks, and recesses, leading to remarkably rapid and efficient cleaning outcomes. It is ideal for cleaning clock parts. A clock sage I know once said, “Wait till you see how clean lantern pinions are after a cleaning’.

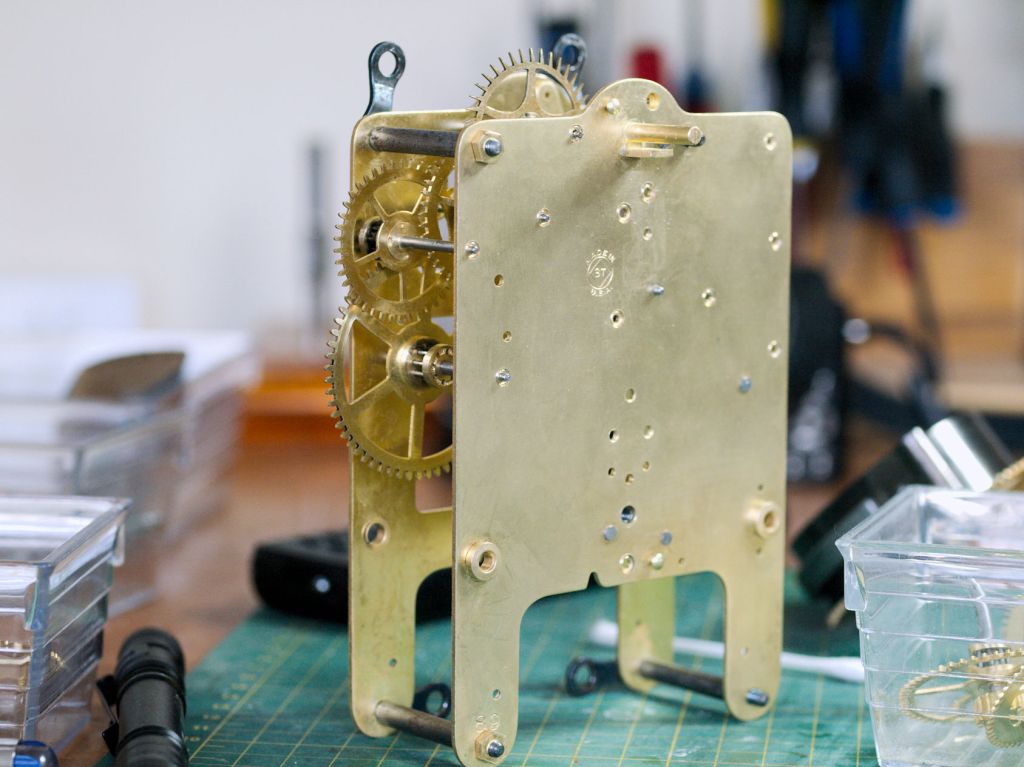

Cleaning a mechanical movement’s parts before reassembling a clock movement is crucial for several reasons:

- Remove Dirt and Debris: Over time, dust, dirt, and other contaminants can accumulate on the various components of a clock movement. Cleaning helps eliminate these particles, preventing potential issues and ensuring smooth operation.

- Prevent Wear and Damage: Dirt and grime can act as abrasives, leading to increased friction between moving parts. This friction can cause wear and damage to components over time. Cleaning ensures that parts are free from abrasive particles, preserving their longevity.

- Optimize Performance: A clean movement operates more efficiently. By removing any buildup that may hinder the free movement of gears, springs, and other components, the clock can function optimally, maintaining accurate timekeeping.

- Identify Issues: Cleaning provides an opportunity to closely inspect each part. This close examination can reveal any signs of wear, damage, or misalignment that may not be apparent when parts are dirty. Identifying issues beforehand allows for timely repairs, preventing potential problems in the future.

- Lubrication: Cleaning is often accompanied by the application of fresh lubrication to key components. Lubrication reduces friction between moving parts, minimizing wear and ensuring smoother operation. This step is vital for maintaining the health of the movement.

Although it is possible to clean clock movement parts by hand, an ultrasonic cleaner offers a more precise and thorough cleaning process.

The following outlines my approach to using an ultrasonic cleaner for clock servicing.

Using the ultrasonic cleaner

In the cleaner’s main tank, I pour in a pre-mix of one part Deox 007 to six parts water. Deox 007 is a biodegradable de-oxidizer and de-greaser and is my recommended solution for cleaning clock parts. While the mix is at room temperature I leave the solution in the ultrasonic machine for 10 minutes or so and use the integrated ultrasonic heater to heat the mixture. Using hot water speeds up the cleaning process, but it’s important not to make it too hot, as it can damage lacquered parts.

When cleaning multiple batches of parts, I check the water temperature to ensure it’s not too hot. If needed, I simply turn off the heater without disrupting the operation of the ultrasonic cleaner.

For heavily soiled movements, I recommend pre-cleaning with degreasing soap and water.

Typically, 15-20 minutes in the ultrasonic cleaner is enough, but timing may vary based on the machine’s power.

A mesh tray or basket might not be included with your ultrasonic cleaner. In the case of my L&R cleaner, the mesh tray was an optional accessory.

Arrange all the components in the tray or basket before placing them in the ultrasonic cleaner. Ensure as much as possible that the parts do not touch each other, and if the basket doesn’t provide enough space, consider having an additional cleaning session.

Once the parts have undergone a cycle in the ultrasonic cleaner, I inspect them to determine if an extra cycle is necessary. If not, I immerse each part in warm water to confirm the removal of any degreasing cleaner residue.

Drying is crucial to prevent rust on steel parts. After the warm bath, I lay all the parts on an absorbent paper towel, and with more paper towels I meticulously dry each part. I use a hairdryer or residual cooking oven heat (on a day my wife is baking bread) to remove moisture from lantern pinions for example.

After finishing the drying process for the clock parts, I go back to the ultrasonic cleaner. I empty the cleaning solution from the device and proceed to clean the ultrasonic cleaner itself with used paper towels from the drying phase. I then store the cleaning mixture in an old vinegar container. Following each use, I assess whether to retain or discard the mixture, opting to dispose of it if it is too murky and dark. It can be disposed of in an environmentally friendly way.

A word of caution for individuals using the heater: if there’s a distinct switch for the heater, there’s a potential risk of leaving it on when the unit is plugged in and lacks a solution in the reservoir. This poses a risk of potential damage to the heating element. Unplug the unit if it is not in use.

Other uses for the ultrasonic cleaner beyond clock repair

Beyond cleaning clock parts, ultrasonic cleaners have diverse applications across various industries and tasks. Some common uses include jewelry cleaning, dental and medical instrument cleaning, automotive parts, optical and eyewear, firearm parts, laboratory equipment, metal and plastic parts, and coins and collectibles.

In Summary

Cleaning a clock movement’s parts is a fundamental step in the maintenance and restoration process. It not only improves the immediate performance of the clock but also contributes to its long-term durability and accuracy.

However, there are exceptions to using an ultrasonic cleaner for clock parts. Ammonia-based cleaners on aluminum can darken brass, and caution is warranted. Avoid putting floating balance escapements and hairsprings in the ultrasonic cleaner as they might be damaged. Old hammered brass movements are best cleaned by hand to avoid potential damage.

An ultrasonic cleaner is a handy piece of equipment to have around the shop.

Authors Note

If a premium unit like the L&R cleaner is beyond your budget, numerous alternatives are available on online retail platforms for you to consider. The most cost-effective alternative is a used machine which can be found online but try to avoid low-cost and low-power jewelry cleaners that have small reservoirs.

The price of the L&R Q-140 has significantly increased over the past five years. When I purchased mine four years ago, it was around $600. However, I’ve noticed that it now costs upwards of $1160, a dramatic rise. Despite my satisfaction with the purchase, such a steep price would make me think twice today. If I were to make the choice again, I would probably opt for a less expensive Chinese-made cleaner and take the chance that it will last.