New owners of an antique or vintage clock might find it surprising that their recent purchase requires periodic maintenance. This realization often dawns upon them only when the clock stops, and they struggle to get it running again.

In this discussion, we explore regular clock maintenance, underscoring the importance of continuous inspection to ensure your clock enjoys a long and functional life.

Determining the ideal service interval of a running clock is a frequent topic of discussion among clock repairers, influenced by various factors that impact a clock’s lifespan. Factors include environment, age, frequency of use, manufacturers recommendations, complexity of the movement, user maintenance and cost of repairs.

Regular inspection

I conduct regular inspections of all clocks running continuously in my collection every 3-5 years, enabling me to pinpoint potential issues and remediate them if necessary.

Not all of my clocks are inspected on a regular basis. Among my collection of approximately 85 clocks, only a maximum of 27 clocks remain in continuous operation. Of the remaining ones, certain clocks may need specialized maintenance, are in various states of repair, some have fragile or rare parts, and others are reserved for special occasions.

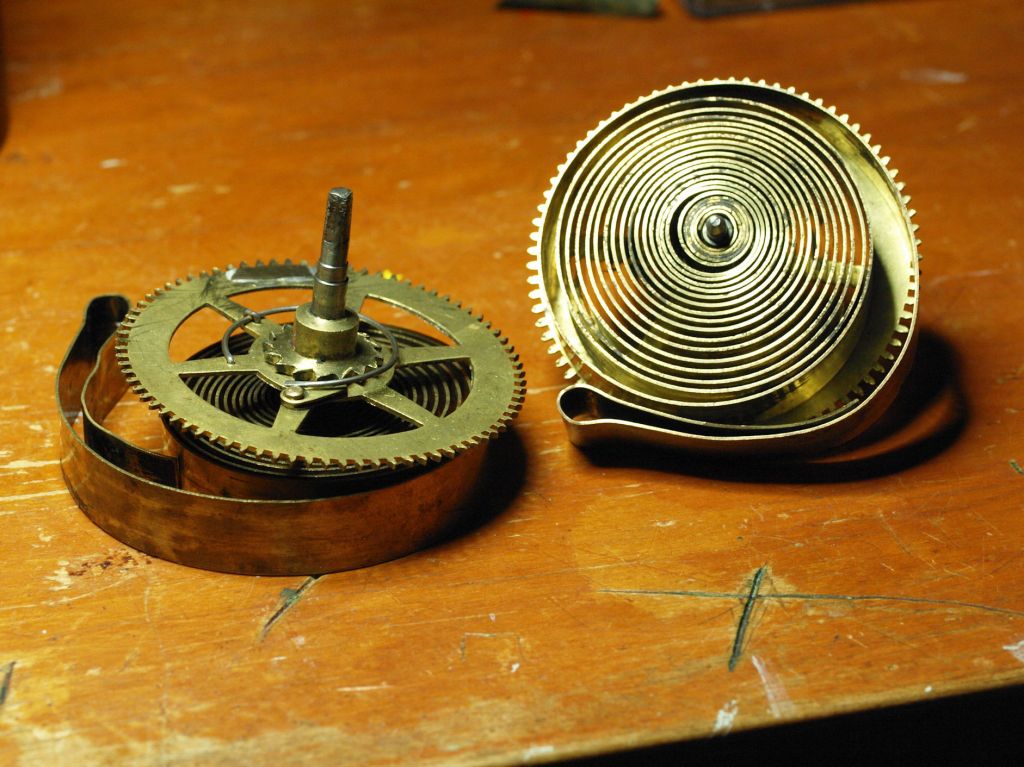

As an illustration of a clock that seldom runs, one of my clocks is a 30-hour time-and-strike Elisha Manross steeple clock dating back to the 1830s. This particular clock features brass mainsprings, making them irreplaceable if they were to break today.

Clocks that occasionally stop signal a need for immediate attention. I look for any immediate issues that might have caused the stoppage otherwise I focus on identifying green or black residues around the pivots. Contaminants mixing with clock oil create an abrasive paste, damaging bushing holes and pivots and in time the wear will stop a clock. If a clock stops after running continuously for years it is more often than not a wear issue. Disassembling the movement is imperative, enabling a detailed assessment of wear and determining the extent of intervention.

When dealing with a non-functioning clock no matter what procedures you have taken to get it running, the first step involves a visual inspection to identify evident problems like broken or bent parts, as well as missing components. This leads to the next step which is called servicing. True clock servicing involves comprehensive disassembly, inspection, cleaning, addressing wear and damage issues, reassembly, and thorough testing.

Factors that affect wear

Several factors affect wear, with the local environment playing a pivotal role. Humidity and temperature fluctuations, especially in older homes or those with wood stoves, impact a clock’s performance. Dust and pet hair, infiltrating the movement, also accelerate wear.

Clock cases that are tightly sealed with access doors help alleviate these concerns, and a properly sealed clock will extend the intervals between servicing.

Different types of clocks exhibit unique wear patterns. Spring-driven time and strike clocks often wear on strike side pivots more often than the time side due to the shock of the half-hour strike. Chiming clocks face additional challenges due to the complexity of the chime/strike sides, where dried oils and dirt cause friction, leading to eventual stops. Weight-driven clocks, especially if not correctly in beat or with twisted cables, may suffer premature stops and require thorough investigation.

A mechanical clock as a decoration

Many people appreciate the decorative allure of antique clocks and opt not to operate them, choosing instead to display them as decorative pieces. However, leaving a mechanical clock unused poses risks.

Time and the environment, rather than operation, cause the most damage. Unused clocks primarily suffer from the thickening of the oil over time and the eventual breakdown of that oil. On the other hand, dried-up oil provides no lubrication for the pivots and leads to accelerated wear. Excessive enlarging of the brass pivot holes by the steel pivots will eventually lead to depthing issues (depthing, which is the correct meshing of one gear in relation to the next is a topic beyond the scope of this article).

Parts left motionless often tend to fuse, and rust accumulates, particularly in humid environments. Although the majority of clocks possess brass plates that are resistant to rust, there is a significant portion of steel components in them that are susceptible to corrosion.

In addition, mainsprings frequently become stuck due to thickening oil, causing the spring to fuse in position.

Running the clock even occasionally such as once per month is essential, enhancing longevity.

Clock cases also need attention

While maintaining the clock movement in good condition is crucial, cleaning the antique clock case is also important for several reasons.

Firstly, a clean case enhances the overall appeal of the clock, showcasing its design and craftsmanship.

Secondly, regular cleaning prevents the buildup of dust, dirt, and grime.

Thirdly, cleaning the case helps preserve the wood or other materials, preventing cracking and blistering and ensuring its structural integrity. I apply Minwax furniture paste wax on certain surfaces to protect the finish and maintain its appearance.

Overall, cleaning the antique clock case ensures its longevity, functionality, and visual appeal, making it an essential aspect of proper clock maintenance.

Health check for clocks

In my controlled home environment, with stable temperature, low humidity, and no pets, I prioritize regular health checks for my clocks as a preventive measure. Yet, due to the controlled environment in my home, I can prolong service intervals to around 4-5 years.

Shorter periods are recommended for clocks in less controlled or fluctuating environments, ensuring timely maintenance and preserving the clock’s longevity. Utilizing an Excel spreadsheet, I meticulously record changes, service intervals, and issues for each clock in my collection.

My goal is to ensure every clock’s durability, preserving them for future generations, and potentially passing them (well, at least some) down to my children.

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

So informative, well done🕰️🕰️

<

div dir=”ltr”>

<

blockquote type=”cite”>

LikeLiked by 1 person

Thank you.

LikeLike