Let me start by saying that opinions on torsion clocks are divided—some people have great success with them, while others absolutely loathe them. Despite their seemingly simple design, they can cause endless frustration, which is why many clock repairers tend to avoid them. Fortunately, I seem to be one of the lucky ones.

I gifted this clock to my daughter three years ago. She chose it for its intriguing visible movement and the convenience of running an entire year without winding. Recently, she moved across the country, and during the relocation, the clock “broke.” “Can you fix it, Dad?” she asked. “Leave it with me,” I replied.

400-day clocks, also known as torsion clocks, have been around for over a century. They were first produced in limited numbers in the mid-1890s, but their popularity surged after 1900. Between then and the 1980s, thousands were manufactured, becoming a favorite choice for wedding and retirement gifts—hence the nickname “anniversary clock.”

The Kundo model featured here dates back to the late 1950s or 1960s, during the height of production. However, with the advent of quartz clocks, mechanical versions quickly fell out of favor.

Kundo is a well-known name in the world of anniversary clocks. The name is a combination of Kieninger and Obergfell, a highly respected German company. Today, the company continues as Kieninger, operating as a subsidiary of Howard Miller USA.

Servicing a 400-day Clock

To service a 400-day clock, I highly recommend using the Horolovar 400-Day Repair Guide as a reference. Can you repair a 400-day clock without it? Yes, but the Horolovar guide eliminates almost all the guesswork.

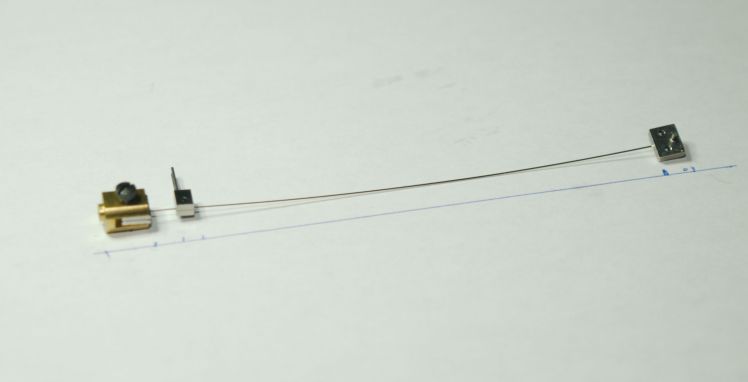

This particular 400-day clock is a Kundo Standard 53, which requires a .0032″ (0.081mm) Horolovar spring. If you don’t have the time or tools to assemble the suspension units yourself, Horolovar (or most clock suppliers) offers fully assembled units. However, these come at a significantly higher cost.

Section 10 of the Horolovar guide includes templates for various clocks. These templates provide precise patterns for positioning the fork and attaching the upper and lower blocks to the suspension wire, ensuring proper assembly.

The screws on the suspension assembly are very small, so using a high-quality precision screwdriver is essential to avoid damaging them. The suspension spring is longer than needed and will require trimming to fit. Once the spring is securely attached to the fork and blocks, it’s ready to be reinstalled onto the movement.

The suspension spring assembly hooks onto the top cock and bottom weights or balls. A threaded thumbscrew on the top base slips into the top block. The bottom block has two pins to which the pendulum hangs. Next are the back spring cover and the locking guard.

Torsion clocks have pendulum locking systems that must be engaged even when the clock is moved just a few feet. Often, the result of an unlocked clock is a broken suspension spring. The locking guard on this clock is an earlier design and looks pretty flimsy in my view but it should work.

Once the spring assembly is installed on the movement it is time to test the beat. The beat should be 8 beats per minute and there should be ample overswing in both directions. A 270-degree rotation is healthy enough.

What makes the 400-day anniversary clock a great addition to a collection?

They are:

- Relatively inexpensive to buy, although some models like Schatz and Gustav Becker are more sought-after and therefore more expensive.

- Very quiet in operation.

- Easy to disassemble, clean, and reassemble due to having few parts.

- Slow runners, meaning wear is rarely an issue.

- A fantastic conversation piece.

- Long runners, with some lasting 400 days or more on a single wind.

What makes them less ideal:

- Notoriously inaccurate timekeepers.

- Can be frustrating to fine-tune at times.

Since I had previously serviced this clock, I was able to loosen the tiny screws on the blocks and fork with ease. Sometimes they can be tight and difficult to remove, but on this occasion, everything went smoothly. As of this writing, the clock has been running well for several weeks.

While it’s currently running slightly fast, small adjustments to the regulating dial will slow it down. However, there’s a limit to how much you can adjust, and it’s not a clock I would rely on for precise timekeeping.

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

I am a collector rather like yourself. Retired (electronics engineer) and coming lately to a lifelong interest that dates from early childhood, in things mechanical and things time. However I do not have all the facilities seen in your workshop. My collection of fairly ordinary examples is far from exotic but allows me to gain confidence over the last 4 more intensive years. I have enjoyed your BLOG and will return to it I’m sure. I came trying to remember the outcome of a previous search for the meaning of “Marque Possee” on a third French drumhead movement to come my way. I was hoping the serial (6331 48) would more accurately date it. I am puzzled how it can be that the same design was made by different makers. Who owned it, and granted the licence to make it?

I also have a collection of 400 day clocks. Much as I have learned about them, still there are some awkward questions and conclusions. I was thinking of offering up some of these but as its your BLOG, it would seem like a take-over. Save to say that they are “challenging.” :<))

Sincerely, BerryG in UK

LikeLike

Thanks and welcome to my blog. Let me think about the offer. Regarding the drumhead movement, have you considered posting on the American clock forum site NAWCC. Registration is free. Although the emphasis is on American clocks there are members from all over the world who might have the answer you are looking for.

LikeLike