I have never been completely happy with how the movement runs in this Junghans Crispi wall clock. When I got the clock in 2017, I jumped right into restoring the case because it was an interesting challenge to put the clock together from a bunch of parts.

Now, eight years later, the clock continues to disappoint. The case remains in great shape, but the movement has been a consistent letdown.

Let’s take a step back in time.

Winter 2017

After completing the work on the case, I turned my attention to the movement. During the disassembly and reassembly process, I accidentally broke not only the strike paddle but also a retention spring. In 2017, my skills weren’t advanced enough to repair the paddle and retaining spring myself, so I had the movement professionally serviced.

During its 2017 service, the paddle was repaired and a new spring was installed. In addition, the movement had received extensive bushing work: six bushings on the front plate and six on the rear.

Three months later, I picked up the clock and hung it on my dining room wall. It ran perfectly for over two and a half years.

Spring 2020

For some undetermined reason, the strike became erratic—it would strike incorrectly, fail to strike at all or strike incessantly until the mainspring ran down.

I had a number of other clock projects on the go so I kept the time side going and left it on the wall until later that year.

December 2020

In December, I disassembled the movement and discovered a slightly bent arbor on the strike side cam wheel. All other pivots were straight, and there were no noticeably worn pivot holes—everything else appeared to be in good condition.

I did notice a small amount of dirty oil around many of the pivots. While I was initially a bit surprised, it’s not entirely unusual after more than two years of regular operation.

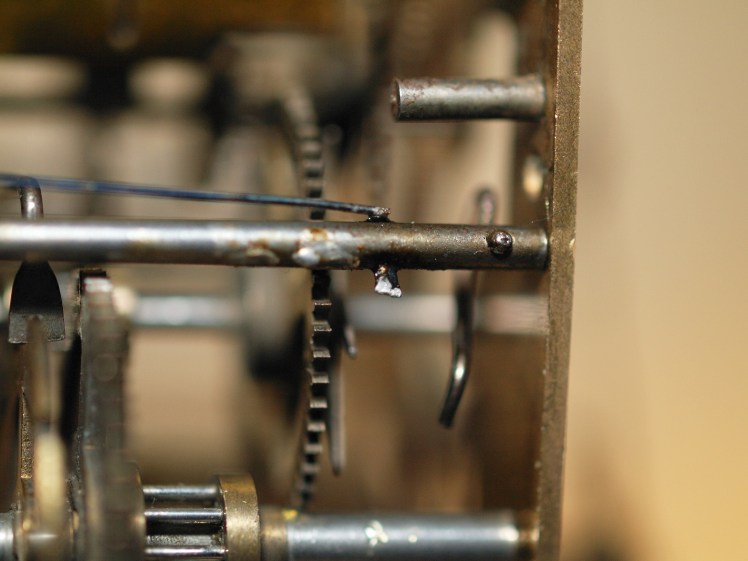

Unfortunately, disaster struck again. While manipulating the plates, I snapped the paddle arbor retention spring—again! This time, however, I was able to repair it myself.

There was just enough of the original spring left to reuse. The wire is very thin (0.5 mm), extremely brittle, and breaks easily under even light pressure. Using a micro drill with a 0.5 mm HSS bit, I carefully enlarged the existing hole in the plate, reinstalled the spring, and secured it with Threadlocker Red to bond it firmly in place.

The movement was reassembled and tested. After the testing period the movement was returned to its case and ran well until about 6 months ago.

Fall 2024

While the time side was running well, the erratic striking returned, and after a few weeks, the clock began stopping just before the warning phase. I wound both the time and strike sides again to replicate the problem, and each time it stopped at the warning point. Feeling frustrated, I left the clock on the wall, wound only the time side, and still it stopped. Since I had other projects to tend to, I decided to leave this one on the back burner for a while.

Spring 2025

Since I was free of immediate projects, I removed the movement from its case and placed it on the test stand. As expected, the time side ran fine. It was serviced not so long ago. For the last couple of months, however, it has been striking erratically or not at all. It enters warning without issue, but seems to almost stall during the striking process. I want to address this issue, but I also want to disassemble the movement to clean up both the pivots and the bushing holes, as the oil is dirtier than I expected.

Judging from similar movements I’ve worked on, I believe there are three issues at play:

- A power issue, which suggests the mainspring is weak.

- One or more bent pivots, preventing the wheels from turning freely.

- The paddle is not correctly positioned in relation to the star wheel. The hammer begins lifting immediately at the drop-off, which stalls the strike train. Once it gets going again, the hammer lifts easily and quickly. I’ll try repositioning the star wheel to allow more run time before the hammer paddle is engaged.

The first issue means replacing the strike-side mainspring. The second issue involves manipulating pivots. There is always a risk of breaking a pivot when attempting to straighten it, not a pleasant experience, as re-pivoting is necessary.

Check back later for an update on what I discovered—which of the three issues turned out to be the culprit, and whether I was finally able to fix a clock that, at times, seems determined not to be fixed.

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

Ron, Stay with it. You are a great diagnostician, identifying the problem is often the biggest headache. You are welcome to borrow my mantra tell myself when stumped:

“The Laws of Physics in the Universe are constant, “there’s no such thing as a haunted _______,”, (add here).”

Always an answer to find, no matter how well it hides itself.

LikeLike