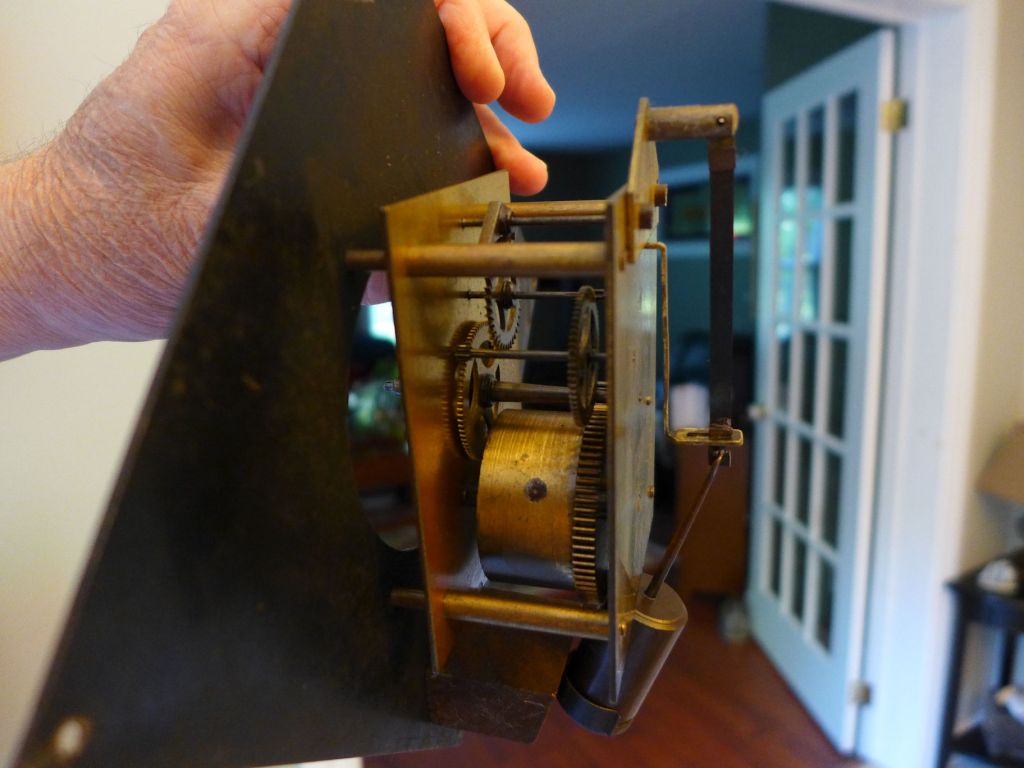

A clock spring barrel is a cylindrical component found in spring-driven clocks. Its primary function is to house the mainspring, which stores energy to power the clock.

The mainspring barrel works like this

The mainspring is a tightly coiled strip of metal that, when wound, stores potential energy. The barrel holds the mainspring in place and allows it to unwind in a controlled manner, releasing energy to drive the clock’s gears and ultimately the hands.

The arbour, a shaft running through the center of the barrel, is connected to the winding mechanism by means of a gear. One end of the arbour accommodates a key, used to wind the spring. The other end of the arbour connects to the movement plate. When wound, the arbour twists the mainspring, storing energy. As the mainspring unwinds, it turns the barrel, which transmits power to the clock’s gear train. And that’s it!

A typical clock may have one, two, or even three barrels.

In a clock with a single barrel, the mainspring powers only a timekeeping train. Clocks with two barrels use one to power the time train and the other for the strike train. In clocks with three barrels, each barrel powers a separate function: one for the time train, one for the strike train, and one for the chime function.

Why remove the mainspring

Part of servicing a clock movement involves checking and cleaning the mainsprings.

Over time, the mainspring(s) can accumulate old oil, dirt, and debris, which can impede its smooth operation. Removing the mainspring from the barrel allows for proper cleaning and lubrication, ensuring the clock runs efficiently.

Removing the spring allows you to apply fresh mainspring oil evenly along the entire length of the spring. But that is not the only reason.

Mainsprings can weaken, crack, or break after years of use.

Removing the mainspring from the barrel allows you to thoroughly inspect it for any signs of wear, fatigue, or damage that might require replacement. If the spring is in good condition but the hook end is cracked, it can be reused by cutting the spring and fashioning a new hook end. However, this will make the spring slightly shorter. This task is best suited for an experienced clockmaker. That said, the most straightforward solution is to simply replace the spring.

If the mainspring is no longer functioning properly (e.g., losing power too quickly, damaged, or completely broken), it must be removed and replaced.

Regular maintenance, including removing the mainspring when necessary, helps prolong the life of the clock and ensures reliable running.

Remove the barrel from the clock movement:

Complete disassembly of the movement is necessary before working on the mainspring barrels. However, it’s worth noting that some German clocks are designed to allow the barrel to be removed without fully disassembling the entire movement, provided that only a broken mainspring needs to be replaced/repaired.

Ensure the mainspring is fully unwound before proceeding. If it is still wound, use a let-down tool to gradually release the tension.

The barrel consists of a cylindrical case and a cap. The cap is press-fitted in place and must be removed.

Hold the barrel in a gloved hand with the cap facing your palm (and the arbour between fingers), then give it a quick tap against a block of wood. The shoulder on the arbour inside the cap is enough to be able to supply even pressure to the centre of the cap and pop it off. This method ensures that there is no damage, and no scratches, plus it’s very simple to do.

Exercise caution to prevent bending or damaging the barrel. Although a screwdriver can be used to pry open the barrel, the risk of bending the cap or causing unsightly scratches is too great.

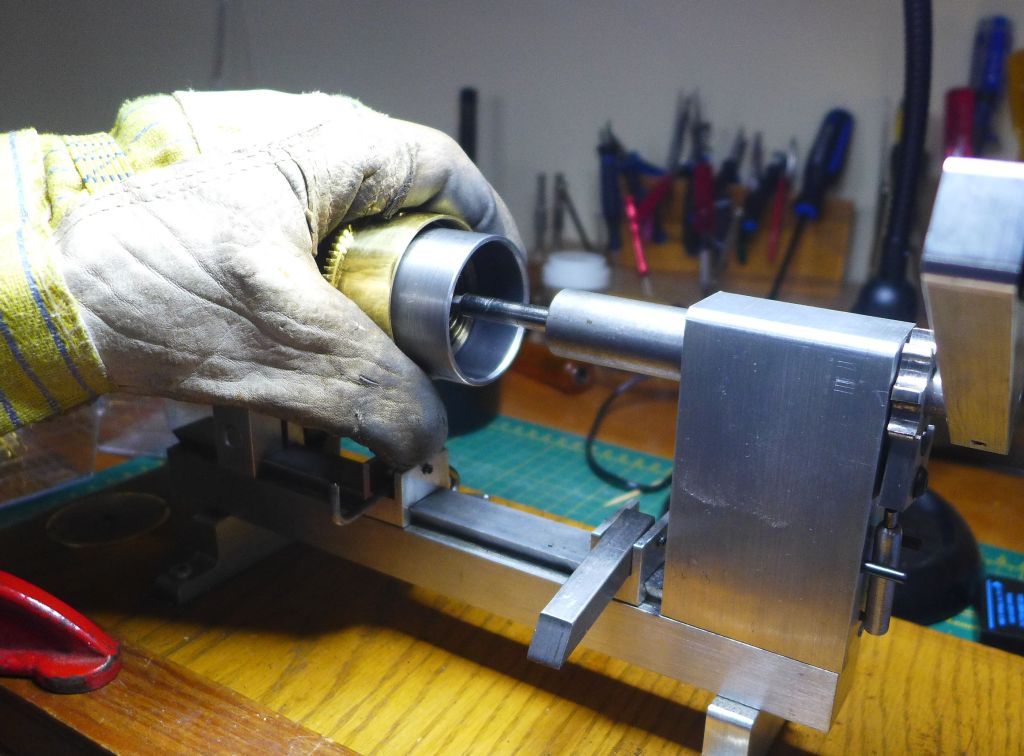

A mainspring winder

Attach the mainspring to a mainspring winder by securing the inner end of the mainspring to the winding arbor of the tool.

Wind the mainspring slightly to loosen it from the barrel walls. Insert an appropriately sized mainspring collar and slowly unwind the mainspring into the collar and then gently remove it from the barrel.

Wind the spring again to remove it from the collar and then relax the spring for servicing.

The mainspring is inspected for damage, dirt, or rust. I use a Scotch-Brite scouring pad to clean the mainspring of dirt and debris. After cleaning, I wipe the spring with a soft cloth to remove any residue, and then lubricate it with Keystone mainspring oil.

After servicing, it is time to reinsert the mainspring into the barrel. Wind the mainspring tightly, place the collar back on, and secure the spring within it. Insert the collared spring into the barrel, ensuring the hook end catches on the notch inside. Finally, remove the collar and carefully unwind the spring into the barrel.

Using a mainspring winder such as one made by Olie Baker is the safest and easiest method for removing and re-installing the spring, as it ensures controlled release.

A mainspring can be removed manually, and there are plenty of YouTube videos available that demonstrate how to do it “properly.”

In Summary

It’s important to mention that there are specific barrel issues, such as broken catches or bulging barrels, which fall outside the scope of this article.

The mainspring barrel houses the mainspring and enables controlled energy release to drive the clock’s gears and hands. Proper maintenance of the mainspring, including its removal for cleaning and inspection, is essential to prolong the clock’s life. Regular servicing, including checking for wear and replacing damaged mainsprings, helps maintain the clock’s performance and longevity.

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

👍

LikeLike

Thank you.

LikeLike

Sent from my iPad

LikeLike

Please resend.

LikeLike

Thanks for the main spring article. I’m getting ready to open and clean my first main spring. The article was very helpful.

LikeLike

Thanks and I hope all goes well.

LikeLike