In the fascinating world of horology, many terms and expressions are often misunderstood or misused. A classic example is the frequent confusion between the words “mantel” and “mantle” to describe certain types of clocks. While “mantel” refers to a shelf over a fireplace, “mantle” is something you wear, like a cloak.

Another pervasive myth is the notion of “over-winding” a clock. How many times have you heard, “It was running fine until I over-wound it”? This phrase is commonly found on clock forums, Facebook groups, and among enthusiasts. However, attributing clock malfunctions to over-winding is a misunderstanding of how clocks operate.

While it is technically possible for a mainspring to be damaged by excessive tightening—winding it until it’s tight and then continuing to wind it further—this is not the primary cause of most clock failures. The real issues often stem from different sources.

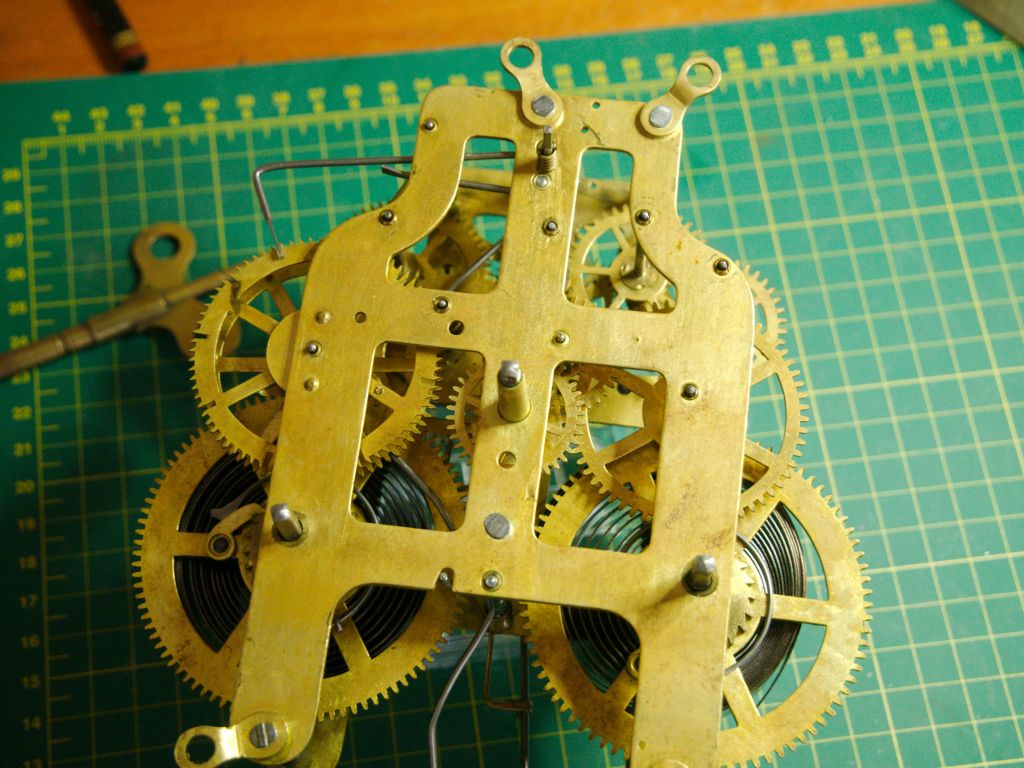

Consider the spring barrel, as shown in the photo below.

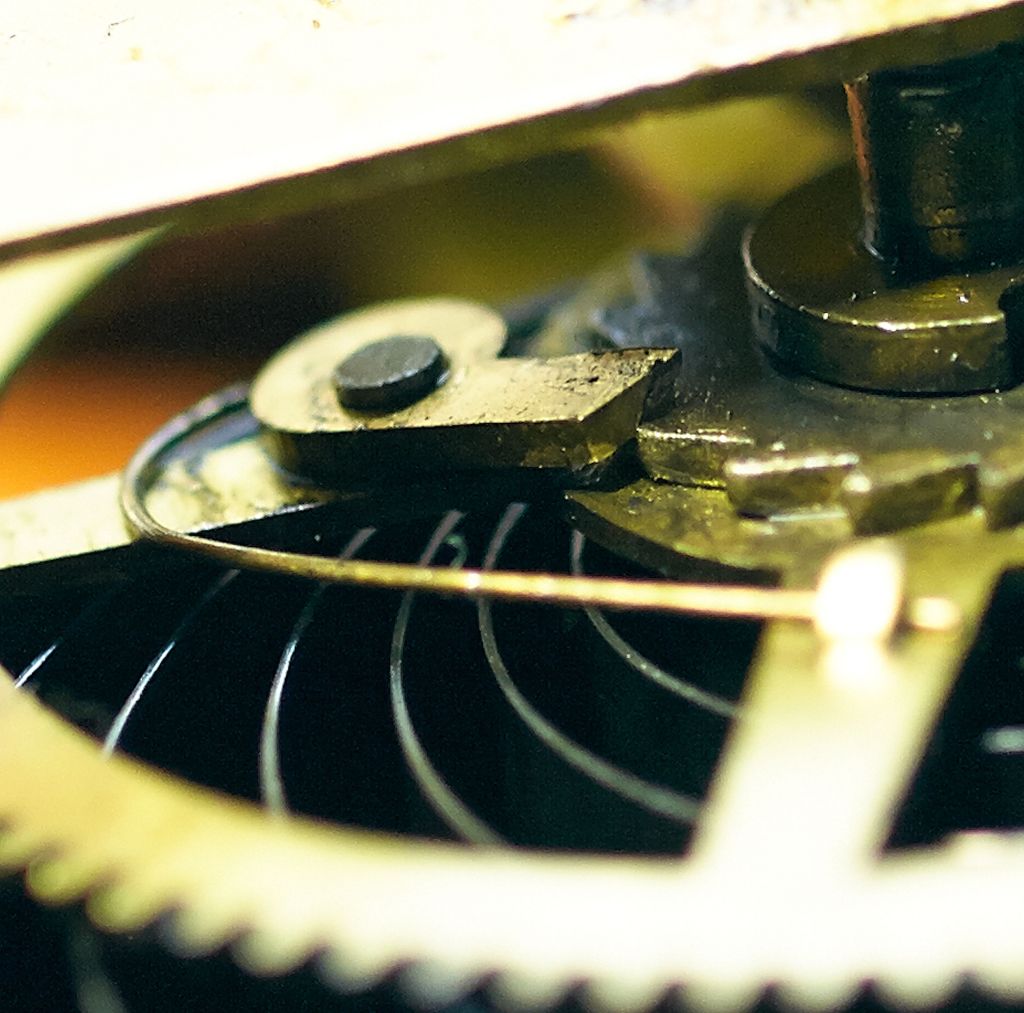

When the spring is wound, it coils tightly around the winding arbor, with the other end hooked to a small stud inside the barrel. This hook can become fatigued over time due to repeated excessive winding or the riveted stud can break free, but this is not the typical cause of a clock stopping.

In American open mainspring clocks, what appears to be “over-winding” is often a result of old oil, rust, and dirt accumulating in the mainspring coil. These contaminants can cause the coil to stick and seize somewhat like the action of an adhesive, making it “seem” as though the clock is “over-wound.”

When I receive a clock that is said to be “overwound”, I use a let-down tool to release the mainspring partially or completely, apply mainspring oil generously, and then rewind the clock. This step will help in some cases, but it’s important to note that it doesn’t replace a thorough cleaning or address other potential issues that might be causing the clock to stop.

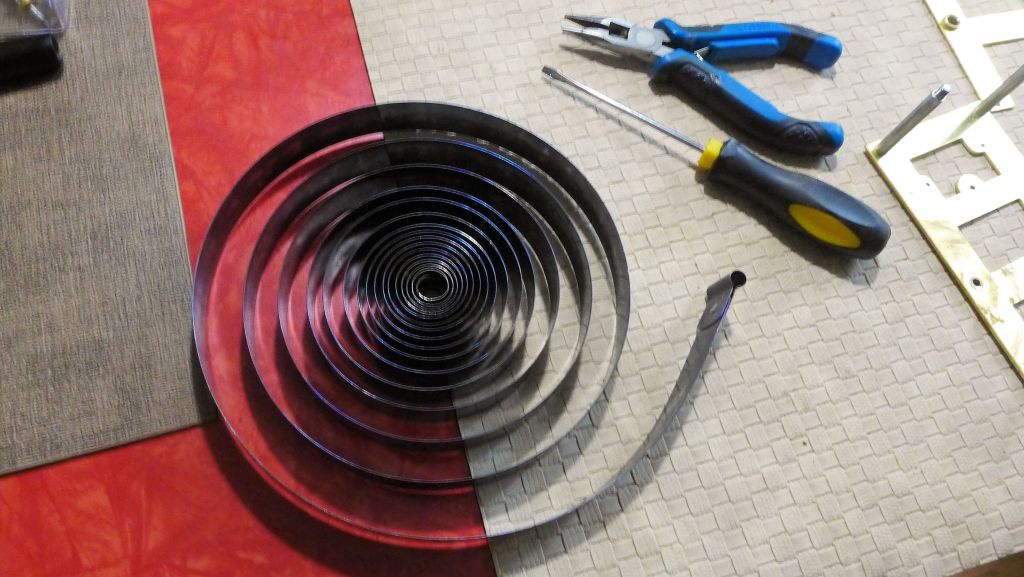

Disassembling the movement and removing the mainspring allows for a proper inspection. Dirt and old oil can be cleaned, light rust can be removed with emery paper or steel wool, and heavy rust necessitates the replacement of the mainspring. The spring should also be checked for cracks or breaks. Often, a mainspring in good condition can be salvaged with proper care even if there are minor problems with the connecting section of the spring.

I frequently reuse mainsprings in my clock repairs, as long as they are not “set.” A mainspring is considered “set” when it has developed permanent deformations or has lost its original flexibility and strength due to repeated use or overstressing. In such cases, reusing the mainspring compromises the clock’s reliability and shortens its operational cycle.

When a mainspring is “set,” I typically replace it to ensure the clock functions optimally and to avoid potential issues. If I were operating a clock repair business, I would replace the mainsprings as a standard practice and pass the cost onto the customer.

Another potential issue is the click mechanism. In some clocks, such as those made by Sessions for example, the click rivets can become fatigued and fail. Inspecting and repairing/replacing this component is a common procedure in clock servicing.

When buying a new clock, do not assume it has been recently serviced unless the seller can confirm it. If there’s no assurance of recent servicing, plan to have the movement serviced as soon as possible either by yourself or a competent professional.

Regular maintenance is crucial for any mechanical clock to ensure its longevity and proper function.

“Over-winding” is a myth that often misguides clock enthusiasts. The real causes of clock issues are typically related to dirt, old oil, or mechanical wear, not the act of winding the clock. Understanding this can help in better troubleshooting and maintaining your cherished antique or vintage clock.

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

another great article Ron. And a word of caution to the new horology hobbyist although it can be done it’s not recommended to unwind and re-wind a spring without a spring winding tool (either a commercial one or a home made version). To do it without one requires that the spring be left intact in the movement like Ron demonstrated in a previous post here. The toughest one I’ve had to deal with was a mainspring in an old crank up phonograph. It was 1” wide and over 12’ long.

LikeLike

Well said.

LikeLike

May I add to, as always, a great blog of yours, this. Especially European clocks, but any clock, there’s a lot of stored energy in the mainspring. If not let down properly, likely will damage movement. Worse, serious injury. Unless confident knowing what one is doing, don’t.

LikeLike

Absolutely, there is little point in getting hurt.

LikeLike

Thank you for the helpful information.

LikeLike

You are welcome.

LikeLike