Mechanical clocks, especially older or larger ones, can pose various dangers during operation and maintenance. In this post, we will cover some of the risks and hazards.

Mainsprings

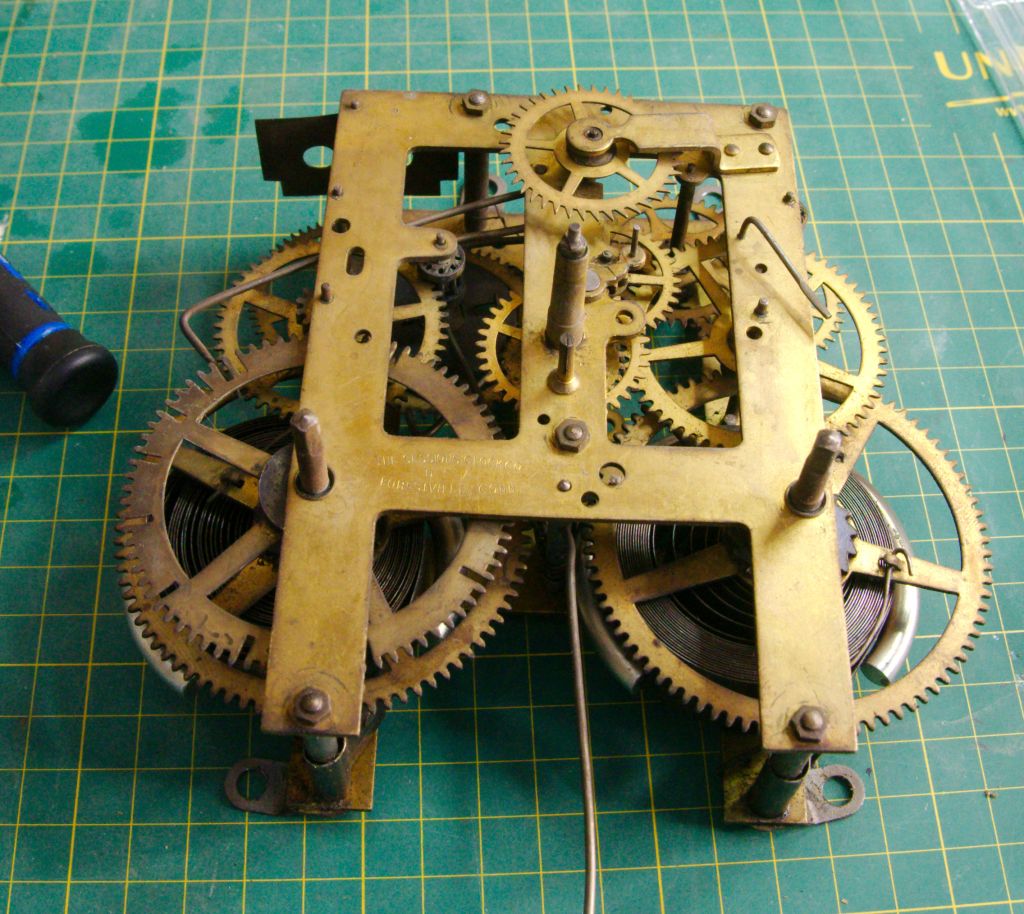

Do not underestimate the power of a clock with mainsprings. Mechanical clocks often use powerful mainsprings to drive their mechanisms. If these components are mishandled, they can release a significant amount of stored energy suddenly (potential energy), with the risk of causing serious injury.

Without the right knowledge and tools, attempting to disassemble or reassemble a mechanical clock can result in damage to the clock and potential injury. When working on a clock and particularly when disassembling clock movements ensure that the mainsprings are safely secured. The best way is to use a specially designed mainspring clamp.

“C” clamps or a strong wire are considered safe methods in clock repair.

Even the simple act of winding a clock can produce a nasty surprise since the sudden release of tension in a mainspring can be dangerous.

I almost lost my thumb when the click let go on the strike side of a Mauthe wall clock while winding it.

If I am unsure of the mechanical condition of a clock particularly one that I have recently acquired, I always wind it with my letdown key set. That way I can control it if the click lets go. If I follow that simple rule I don’t get hurt.

Gears and sharp components

The gears, escapements, and other moving parts can cause pinching injuries. These parts may also be sharp or have pointed edges, increasing the risk of cuts.

The delicate nature of some clock components, such as thin gears or escapement wheels, can break easily. Working on them without proper knowledge or tools can damage the clock and possible injury from sharp, broken pieces may result.

Mercury

Some antique clocks may contain materials known to be hazardous, such as mercury in pendulums or lead-based solder. Exposure to these materials can pose health risks. For example, most American-made crystal regulator clocks have nickel slugs in glass vials for the pendulum that resembles mercury at first glance. They are completely safe to handle.

In contrast, French-made four-glass clocks often contain actual mercury pendulums, which if handled can pose a poisoning risk. The purpose of mercury is to maintain accurate timekeeping despite temperature variations.

The degree of mercury toxicity depends on how much contact one has with it. Here is an excellent article I found on the risks involved and precautions when handling mercury.

Electric clocks

Early electric clocks can pose a significant risk of electric shock if not properly handled or if the wiring is faulty. These clocks are often improperly grounded, and may have worn cords with exposed wire. Those that run hot to the touch when operating are particularly dangerous. Switches and knobs and other components are designed according to past standards and lack the safety protocols of today’s designs.

The danger of electric shock may increase during maintenance or operation.

Electric clocks are best handled by individuals knowledgeable about electrical components and their operation.

Radium

Clocks, especially older alarm clocks with luminous dials can pose a significant risk. The culprit is radium. Even a clock that has lost its luminescence may still have traces of radium on its dial or particulate matter that has fallen from the clock-face making them equally dangerous.

As much as you may be curious about how these clocks work, leave them alone and appreciate them as decorations or alternatively, safely dispose of them.

It must be emphasized that Inhalation or ingestion of flakes or dust containing radioactive materials is extremely dangerous.

Clock tools and equipment

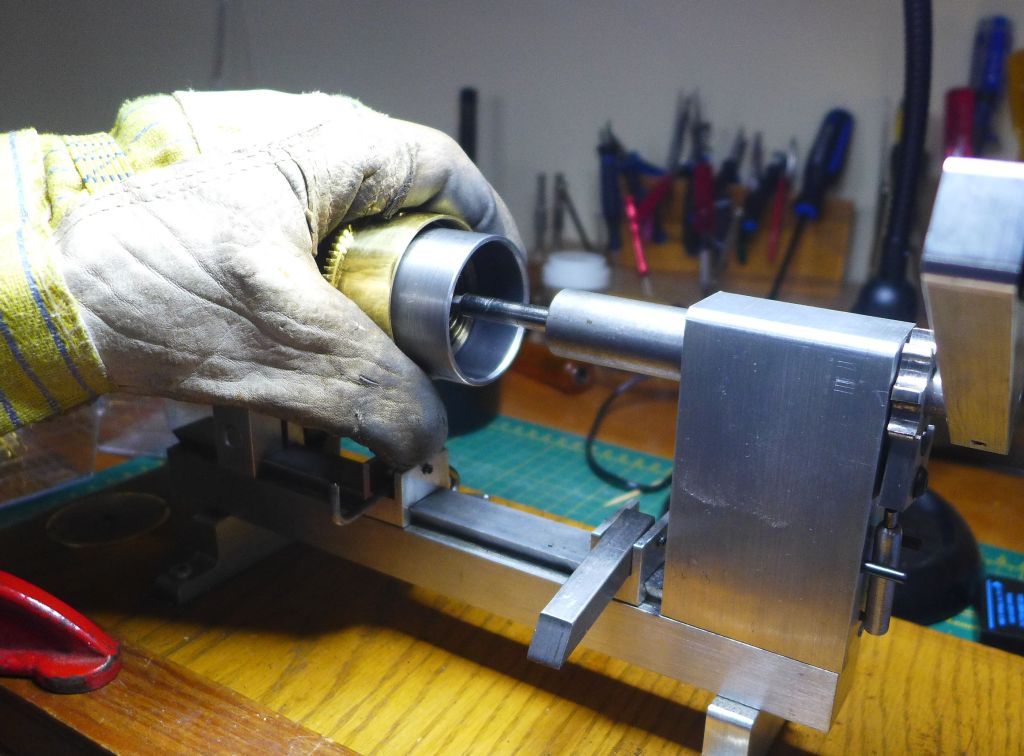

When working on clock springs or components when there is a potential risk of injury or with tools like a lathe, consider wearing leather gloves, and an apron, along with face/eye protection as needed.

Gloves and safety goggles are an important consideration when working with mainsprings. A winding arbor breaking in a mainspring winder or a mainspring letting go while winding it up might result in the spring, wheel, and arbor flying around the room and possibly toward the repair person.

Using a Dremel machine without proper eye protection, especially with wire brushes that rotate at high speeds, can easily lead to serious eye injuries if a piece of wire breaks off.

In sum

To mitigate all risks, it is important to have a good understanding of the clock’s mechanism, use appropriate tools, follow safety procedures, and possibly seek training or assistance from an experienced clockmaker. If you ignore common sense, accidents are sure to follow.

Those new to clock repair may be eager to dive in and take things apart. However, a slow and cautious approach with a focus on safety will reap benefits in the long term.

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

Good point about electrical vintage clocks. I have a beautiful, perfectly functional late ’40’s -early ’50’s Seth Thomas “Baxter” mantel clock that occasionally I touch to make sure it isn’t overheating. I also have it plugged into a surge protector.

LikeLike

I prefer not to work on them. Standards back then were much different.

LikeLike

I have a Seth Thomas mantel clock. How do I wind it safely. And how do I find out it’s worth. The mechanism has 89 C stamped on it

LikeLike

The type 89 movement is very well made and will last a long time. To wind it insert a key into the 2 or 3 winding arbours and turn each arbour till you cannot turn it anymore. Set the hands to the correct time and give the pendulum (if it has one) a push. Unfortunately these clocks do not hold much value and unless it is special in any way you will be disappointed in how much they are worth.

LikeLike