In Part I, I explained the importance of bushing to mitigate wear on a mechanical clock movement.

In summary, bushing involves replacing worn brass around a pivot by drilling a new hole and inserting a new bushing, either using a bushing machine or hand tools. Severely worn pivots may need re-pivoting, which involves installing new pivots using a lathe. Minor wear can be managed with filing, polishing, and burnishing. Proper bushing and pivot work are crucial for maintaining clock movements, extending their lifespan, and ensuring reliable operation.

Now that we understand bushing wear, it is time to proceed with the bushing process.

The process of bushing a mechanical clock plate involves several steps to restore the worn pivot holes to their original condition. Here’s a detailed description of the process:

Disassembly: The clock movement is carefully disassembled, and the clock plates are removed to access the worn pivot holes. Resist the temptation to immerse the entire movement in a cleaning solution. Although this might offer a temporary fix, it prevents proper assessment of the pivots and pivot holes for wear.

Cleaning of all parts: While manual cleaning with a solution is satisfactory, using an ultrasonic cleaner and a solution specifically designed for such a machine, yields better results by ensuring all dirt and grime are thoroughly removed from the brass and steel parts. The cleaning process also includes thoroughly drying all the parts.

Identifying Worn Holes: Each pivot hole is inspected for wear. Worn holes are typically oval-shaped due to the pivot’s repeated movement. I use a marking pen to identify those pivot holes that require a new bushing. I generally work on one train at a time, leaving the main wheels out during this process. I reassemble all the wheels of one train between the two plates, checking for wear by turning and pushing on the wheels. This allows me to observe any lateral movement and see how the gears mesh with each other.

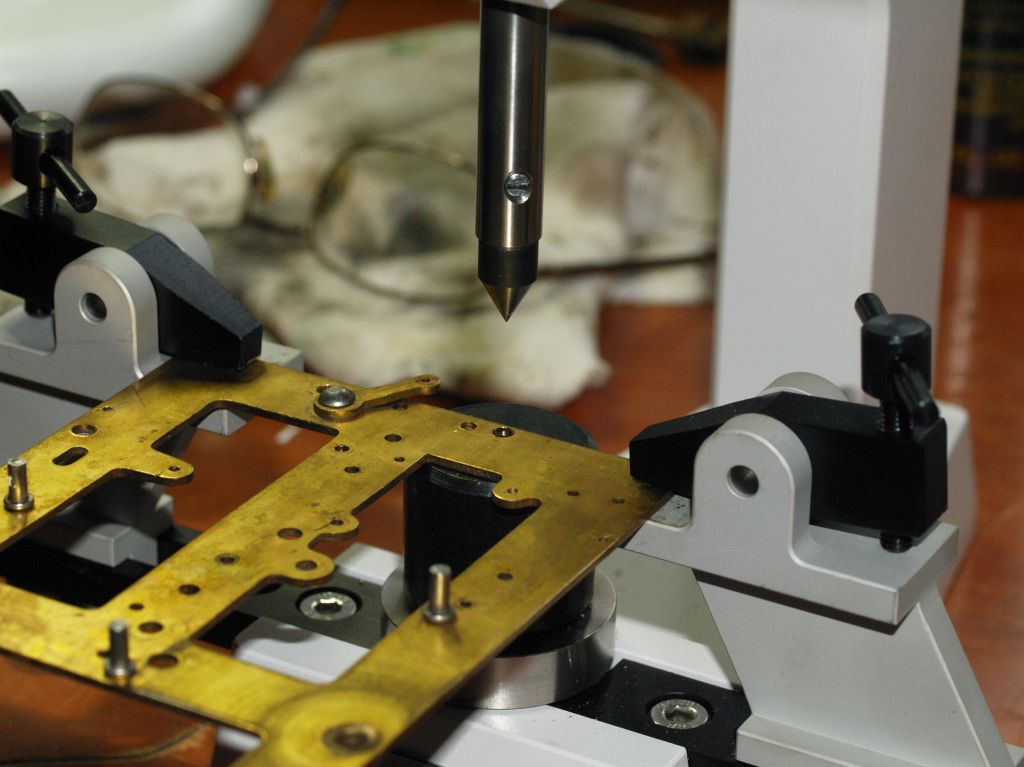

Centering and Drilling: A bushing machine with a centering tool is used to precisely center the worn pivot hole.

A new, round hole is then drilled into the clock plate. This hole must be accurately positioned to ensure the clock’s gears will mesh correctly.

Selecting the Bushing: An appropriately sized bushing is chosen to fit the newly drilled hole. The bushing is usually made of brass and should match the original hole dimensions but is made larger than the hole to ensure a tight fit. For the Bergeon Bushing Machine, Bergeon brass bushings are used.

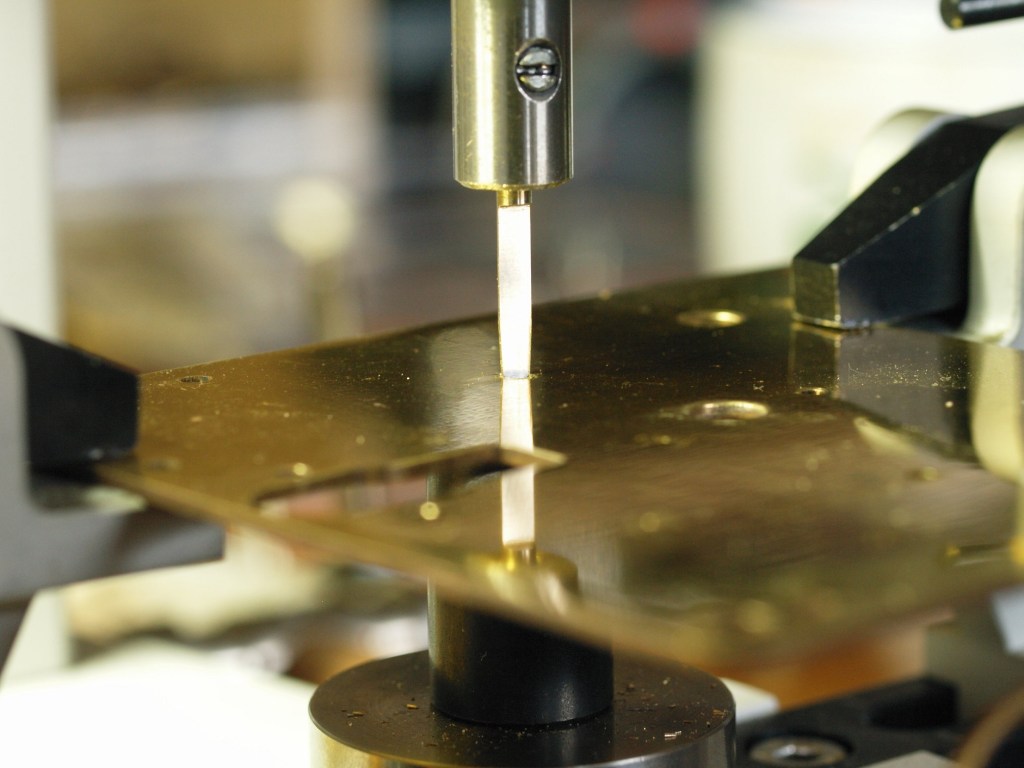

Pressing or punching the Bushing: The selected bushing is pressed or punched into the newly drilled hole. This can be done using a bushing machine, which ensures the bushing is inserted straight and flush with the plate. If done by hand, reamers and smoothing broaches are used to achieve a similar result. A chamfering bit, which does not come with the Bergeon Machine, is used to gently cut the edge of the bushing hole to ensure that the bushing is punched or pressed in neatly.

Reaming the Bushing: Once the bushing is in place, it is reamed to the correct internal diameter to fit the pivot. Reaming is achieved by using a five-sided reaming broach sized to fit the hole. Following the reaming process, a smoothing broach is used to smooth the walls of the bushing hole. A toothpick is then used to clean the hole and remove any debris left behind by the broaches. This entire process ensures that the pivot will rotate smoothly without excessive play.

Polishing and Burnishing: The pivot that will run in the new bushing is polished and burnished to reduce friction and wear. A metal lathe is an indispensable tool for this procedure. This step is crucial for the longevity of the repair.

Reassembly: The clock movement is reassembled, with the newly bushed pivot holes ensuring proper alignment and smooth operation of the gears. Clock oil is applied before the testing phase.

Testing: The reassembled clock is tested to ensure that it runs accurately and reliably. Any final adjustments are made to fine-tune the movement.

The process of bushing a mechanical clock plate involves disassembly, identification of worn bushing holes, precise centering and drilling, selection and insertion of appropriately sized bushings, followed by reaming, polishing, and burnishing of the pivot. Finally, the clock movement is reassembled and thoroughly tested to ensure accurate and reliable operation.

By following these steps, the worn pivot holes are restored, improving the clock’s performance and extending its lifespan.

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

You must be logged in to post a comment.