My apologies for the wordplay in the title. I recently encountered an issue with the striking mechanism in a German clock I’m currently repairing, and in this article, I would like to describe my experience with the repair.

I have to admit it is a frustrating problem that could have been a disaster but I came up with a solution that should work.

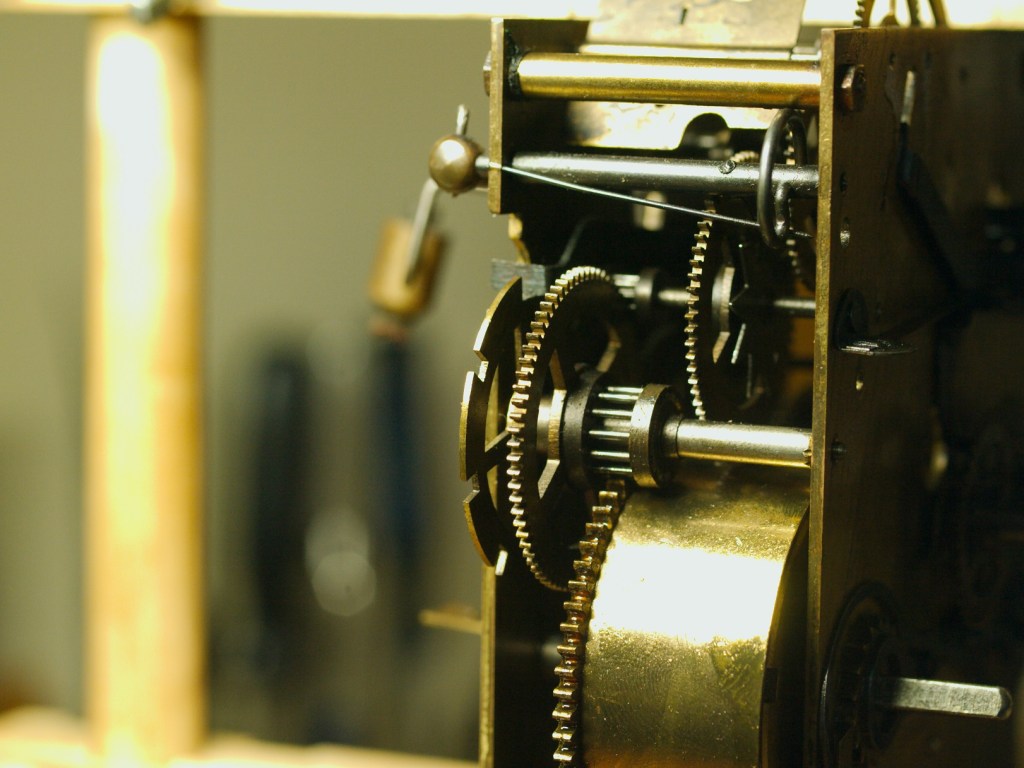

The other day I was investigating why the strike side of a Junghans time and strike movement was not functioning correctly and discovered a portion of a small stamped metal part on the exterior of the movement had bent.

I had simply pried too hard when unbending a part of the stamped metal piece and it snapped off, which surprised me. It was a very small piece and when it flew off it was hidden in the clutter of my work area but I was successful in retrieving it. Without that small piece, I was not certain I could make the repair.

Perhaps I do not have the correct name for the part that bent but let’s call it the strike actuator. The strike actuator when activated lifts a lever to begin the strike process. The activator is attached to the front plate with a small machine screw and is free to move.

On the center arbor is a star cam. The 2 points on the star cam rotate every 30 minutes until a star point pushes the strike actuator to begin the strike sequence. A protruding piece of metal, the contact piece for the star point on the actuator, is the part that broke as I was attempting to unbend it.

Needless to say, I was crestfallen. What do I do now!

There are essentially three ways of addressing a situation like this.

If I had enough spare parts, the straightforward fix would be to replace the problematic part by taking it from a donor movement. However, whereas I have an ample supply of spare American movements for American clock repairs, unfortunately, I lack spare German movements for parts.

To my knowledge, there is no established source for Junghans clock parts. While clock parts suppliers offer various components for common repairs like escapements and mainsprings, smaller parts like this are typically not readily available in their inventory.

The second solution is to simply have a nonfunctioning strike side but a clock that at the very least, tells the time.

The third alternative involves undertaking a repair, as there appears to be a potential for some sort of restoration. So, I chose to fix it. Although I cannot assure the repair’s absolute success, my intention is to conduct thorough testing to assess its effectiveness.

The Repair

To repair the actuator there is no need to disassemble the movement. One small slotted screw holds it in place. Release the screw and it is ready to be worked on.

To repair the actuator, I used a high-temperature butane torch along with a solder containing a significant amount of silver. It comes in spools and looks much like aluminum wire.

Silver solder is known for its higher melting point compared to other solder types, ensuring greater durability and reducing the risk of weld cracking.

Using hobby alligator clamps, I securely held together the broken piece and the actuator, eliminating the need to handle the pieces manually. After securing them, I dabbed flux in the weld area and then applied heat until the metal changed color and then proceeded to apply the solder.

The challenging part involved aligning the fractured piece onto the actuator. I had to carefully maneuver the clamps to ensure they were positioned correctly for the welding process. The actual soldering was the easy part and literally took seconds.

After a few minutes, I reattached the actuator. I then wound both the strike and time side of the movement and observed the action of the actuator as it went through the strike sequence. It worked!

I plan to keep the movement on the test stand for a couple of weeks or more but after running it for four days the weld has held.

Final thoughts

Tackling the repair of the actuator in this Junghans clock posed its challenges, particularly in aligning and securing the broken piece onto the actuator. Importantly, in any clock servicing, mistakes may occur, but it’s crucial to remember that there are ways to address and rectify many errors. Whether through additional adjustments, alternative techniques, or seeking guidance, the learning process in clock repair involves both successes and challenges.

In the end, the commitment to problem-solving enhances one’s skills, making each repair experience a valuable lesson in the pursuit of clock repair.

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

No intention of sounding schadenfreude here. Glad though, this happened to you. Even a experienced repairer as yourself can end up doing damage. Encouraging too, a shared solution. Now its up to me to undo a botched repair.

LikeLike

There is not a lot of stress on this part so, I think the “fix” should survive.

LikeLike

This blog is really useful to me,thanks.

I’ve been into clocks for about 5 months.I find it very interesting.

I’m in the UK and have a tiny one by Marksman.Are they German?Do you know anything about them?

Keep up the good work!

Thanks again.

LikeLike

I’ve not heard of it. Can you send a photo at ronjoiner@antiquevintageclock.com

LikeLike

I don’t know if they have Junghans’ parts, but they were very helpful with parts I needed for a Badische clock; I dealt with Henri.

Best, Peter

Sent from my iPad

>

LikeLike

Interesting. What was the name of the company? This one: https://antiquedutchclockparts.nl/about/

LikeLike

Sorry for my poor wording. It’s:

Sent from my iPad

>

LikeLike

I went to the site and I think it is a great resource for those hard-to-find German and other European clock parts. Thank you very much!

LikeLike