Last week I began working on a Junghans round top mantel clock. For first impressions and background information about the clock itself, you can find the article here.

During this segment of the maintenance process, my attention will be focused on the mainsprings.

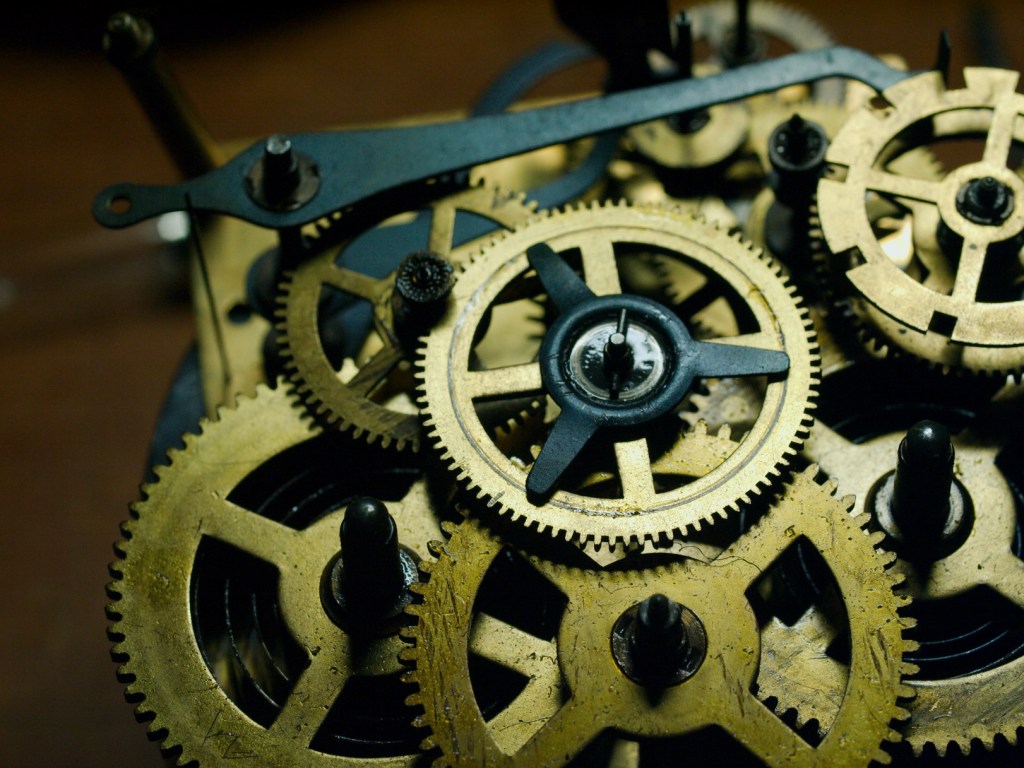

Upon my initial assessment, it appeared that the movement was found to be in decent condition, overall. A noticeable accumulation of dirty oil in the majority of pivot holes told me that a thorough cleaning was necessary.

Upon closer inspection, elongated pivot holes in three locations tell me that new bushings need to be installed: specifically, on the third wheel time side, back plate, and both the front and back plates of the star wheel. The star wheel runs off the count wheel and it is the star points that activate the hammer for the strike.

But first, let’s focus on the mainsprings.

In my experience neglecting certain steps during clock servicing can result in potential future complications.

For example, there is a temptation to overlook the mainspring barrels, yet it becomes evident that unless one is confident about the absence of accumulated dirt and grime within the spring barrel, certainty can only be achieved through disassembly. Moreover, the open design of this particular barrel increases the likelihood of dirt penetrating the springs.

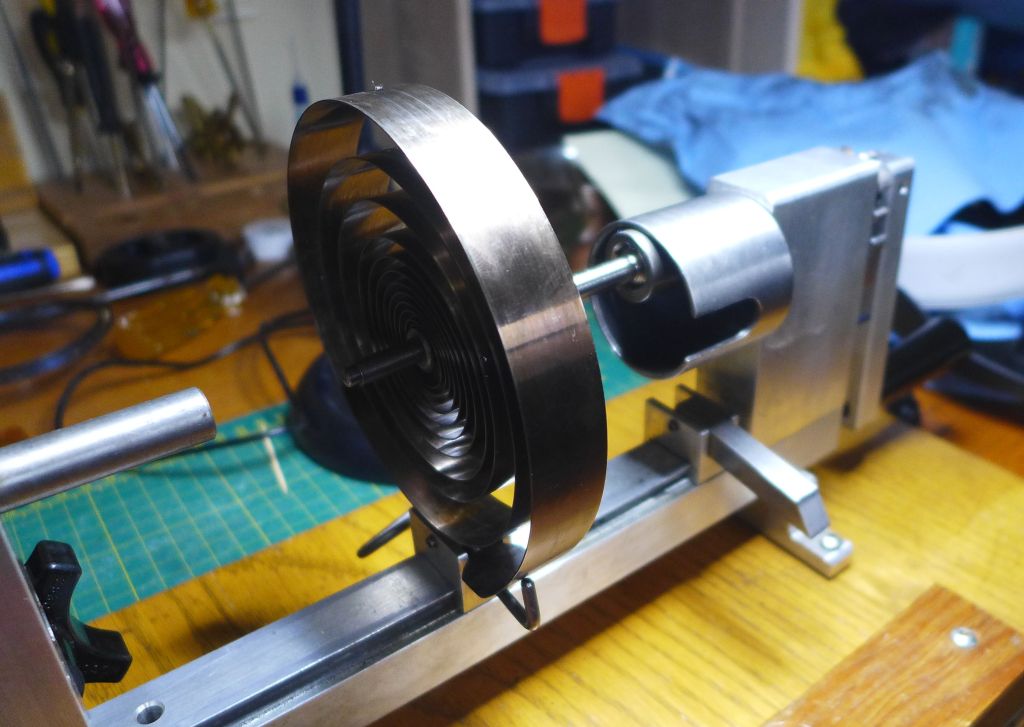

While mainsprings can be removed from their barrels by hand and subsequently coiled back in by hand, a mainspring winder, such as one made by Olie Baker, is an essential tool for the serious repairer.

Removing and reattaching the caps to any barrel can be quite cumbersome. With this particular barrel, a convenient and swift method involves using a small slotted screwdriver in one of the two small openings to easily pry open the cap.

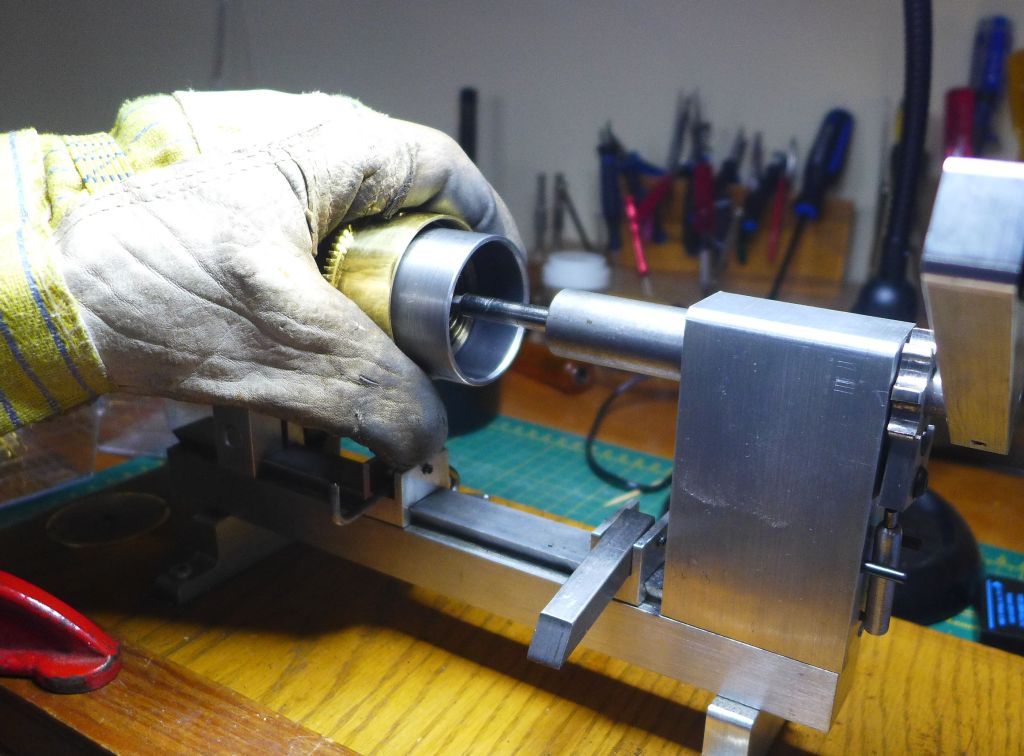

The importance of wearing leather gloves for safety cannot be overstated.

A firm grip on the barrel ensures a predictable and controlled process.

During the removal of the mainspring, a thorough inspection is conducted to identify potential issues such as stress cracks, unusual wear, pitting, and the accumulation of rust. Subsequently, the spring undergoes a meticulous cleaning process to eliminate any dirty oil, followed by reoiling, before being reintegrated into the barrel.

Reattaching the cap to the barrels can be accomplished by employing two small clamps to gently guide the cap into position.

Once more, the use of gloves guarantees safety.

Upon proper placement, the cap will emit a distinctive “snap” sound.

The springs in this particular clock appeared to be in excellent condition and are suitable for reuse.

Meanwhile, it is essential to inspect the barrel teeth for signs of wear, particularly focusing on any bent or damaged teeth during this stage. Worn teeth may result from a spring that is too powerful and not correctly rated for this clock, while broken or bent teeth could be indicative of a mainspring failure.

Next, we proceed with the remainder of the maintenance for this time and strike clock, moving on with the polishing of pivots and bushing work. Join me in a few days as we continue the servicing of this Junghans movement.

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

How much oil do you add to the spring, and where? I assume if you add a few drops in the middle, it will not be spread to the rest of the spring as it does not move around much like a gear.

LikeLike

Firstly, I use Keystone mainspring oil. During the process of cleaning the mainspring and as the mainspring is uncoiled, I oil a soft cloth and wipe the spring with it ensuring that all of the spring is covered. Ron

LikeLike

Thanks Ron! Good to know. Makes sense, using a cloth.

LikeLike