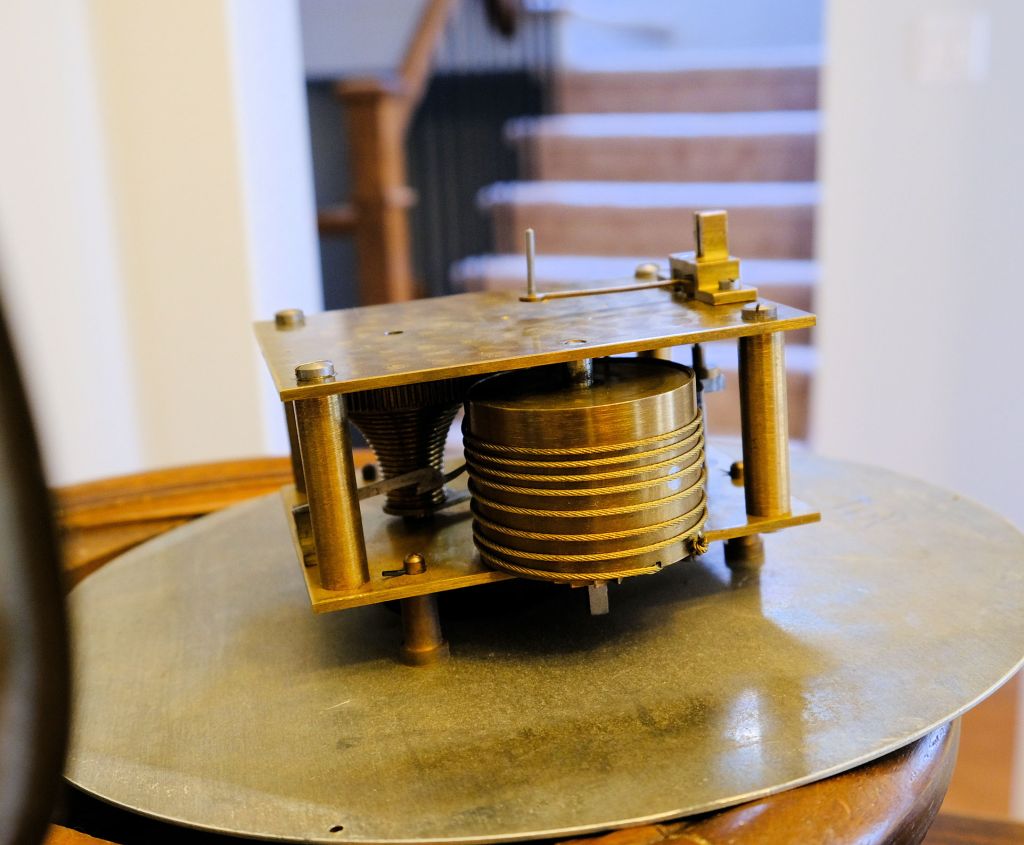

A fusee clock movement is a type of mechanical clock mechanism that uses a conical pulley (the fusee) and a chain or cable to provide a more consistent driving force to the clock’s gear train. The fusee mechanism was commonly used in early pocket watches and large clocks to compensate for the decreasing tension of the mainspring as it unwound.

As a typical mainspring winds up, its tension is strongest, which leads to the clock running too fast. As the mainspring unwinds, its tension weakens, causing the clock to run slower. The fusee counteracts this by gradually changing the ratio of the force applied to the gears, ensuring a steady, regulated power supply. This innovation helps the clock maintain accuracy throughout its entire run.

Fusee movements are often considered an important step in the evolution of horology, showcasing the ingenuity of early clockmakers in solving the problem of maintaining consistent timekeeping. Today, they are still highly valued by collectors and horologists for their craftsmanship and historical significance.

Most fusee movements were equipped with anchor escapements, though some featured lever or deadbeat escapements. Earlier fusee movements often had decorative sculpted pillars and pins to secure the plates, while later models used plain pillars with screws. This difference in design is one way to determine the age of the clock.

Jacob Zech is credited for inventing the fusee in 1525 although drawings of a fusee appear in Leonardo De Vinci’s notebooks.

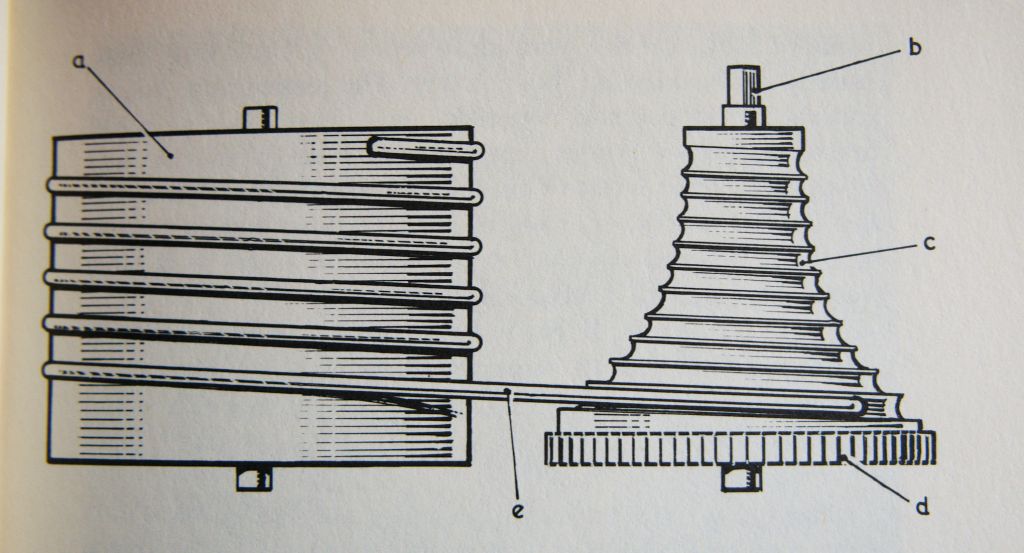

Parts of a Fusee Movement

a) Spring drum

b) Winding arbour

c) Fusee

d) Main wheel

e) Chain (or gut or wire)

Of course, the above diagram does not show the wheels above the main wheel and merely illustrates the essential components of the fusee section.

A chain-driven fusee is the norm although wire and gut are common. Gut was used at first but around 1650 chains began to be used, which lasted longer.

How does it function?

The spring drum’s axis is parallel to the axis of the fusee. Around the drum is wound a chain that is attached to the fusee at its largest diameter. An attached mainspring is coiled inside the drum that sits next to the fusee.

When the key is inserted into the arbour of the fusee it pulls the chain causing the drum to rotate. Because the inner end of the spring is attached to the drum, the drum rotates until the spring is completely coiled. The spring is then at its maximum tension. At full winding, the chain is completely wound onto the fusee.

As the spring begins to uncoil the chain is on the smallest diameter of the fusee. The pull on the spring drum becomes less as the diameter of the fusee increases. The diameter of the fusee becomes larger giving greater leverage.

The greater turning moment provided by the larger radius at the fusee compensates for the weaker force of the spring, keeping the drive torque constant and that is why fusee clocks are better timekeepers than conventional spring clocks.

Fusee movements are generally more expensive than conventional spring drive movements. Double and triple fusees add to the cost and complexity.

Disadvantages of fusee movements include their difficulty to adjust. If the fusee chain breaks, the force of the mainspring can send the end whipping around inside the clock, potentially causing damage. Any collateral damage, if present, must be repaired as part of the restoration. Additionally, if a replacement mainspring is needed, it must be an exact match; otherwise, the fusee will need to be adjusted to accommodate the new spring.

Despite their complexity and the challenges involved in servicing them, fusee clocks have maintained their value over the years and continue to be highly sought after by serious collectors.

Discover more from Antique and Vintage Mechanical Clocks

Subscribe to get the latest posts sent to your email.

You must be logged in to post a comment.