When I bought my Ingersoll-Waterbury clock a year ago I knew that it had not been serviced but the price was reasonable and it was running. I got a lot of other projects out of the way and have finally gotten around to giving this clock a little care and attention.

Ingersoll-Waterbury clocks were sold in Canada; had Canadian made cases using American made Waterbury movements and were sold in department stores across Canada. This clock was distributed by the G. R. L’Esperance Co. from Montreal, Quebec. The label on the inside of the back access door says “Ingersoll-Waterbury Co. a division of Waterbury Clock Co.”. Ingersoll-Waterbury was the Canadian arm of the Waterbury Clock Co. Year of manufacture, I am estimating was somewhere between 1940-1944 when brass was in short supply.

The case is in very good shape though it was likely inexpensive to make. Some cost savings are evident in the use of a paper dial, flimsy clock hands and a plastic bezel with flat glass. However, I was impressed with the well designed and sturdily built movement and surprised that it did not take much to service this clock.

One unique feature is a swinging door with plastic bezel and flat glazing attached to the case by two hinges that open up to reveal the clock face and hands.

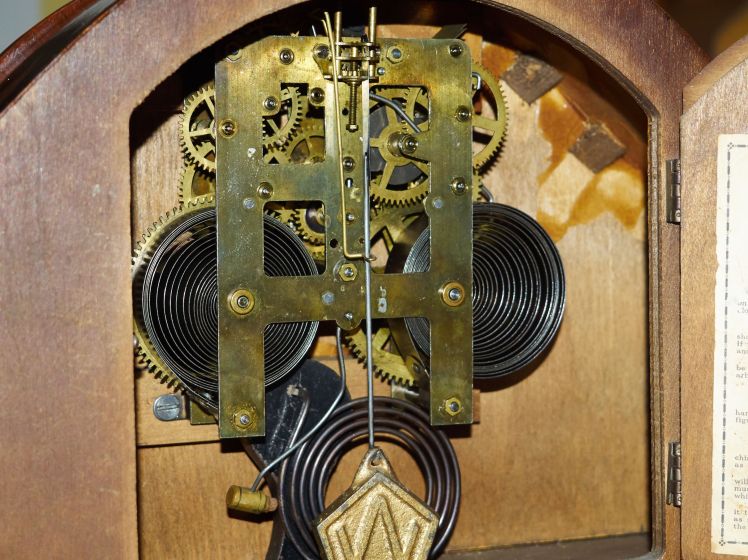

The clock has a steel frame with a brass electro-plating as a rust inhibitor and brass bushings punched into drilled holes in the steel. Steel plates are not unusual as there were a number of manufacturers which used steel as a cost savings measure, for additional strength or because brass was in short supply. The plates were often plated with nickle as in the case of Arthur Pequegnat clocks or brass as in the case of this clock. One of the first things I noticed when I dis-assembled the clock were the number of punch marks adjacent to the bushings an example of which can be seen in the next photo. It must have been difficult to achieve a tight fit for the brass bushings; factory punching ensured that the bushings remained in place.

I have just completed the servicing. The clock required three new bushings. Punching new brass bushings into the factory bushings took a little more care and attention than usual as I did not want to loosen the existing bushings.

Dis-assembly, cleaning, servicing the mainsprings, installing new bushings are no different than any other American movement. Re-assembly of the strike side requires the synchronizing of the strike side by aligning the levers and wheels correctly which usually takes several attempts for me.

The one real challenge I had was aligning the strike hammer so that it would actually strike the gong. I must have bent it when I took the clock apart. What was I thinking? I could not see the solution so I put it aside until I came up with the fix. I ended up bending it back to its correct position.

While re-installing the movement into it’s case I noticed something strange on the bottom of the clock, a mysterious hatch. On the bottom right hand side of the clock (indicated by the arrow) there is a hatch that measures 2 3/8 inches by 2 3/8 inches. On it there is an inscription which reads

“FRONT, if you know what this hatch is for, you know more than I do” signed J.H.Ross May 24, 1967.

“Front” refers to the orientation of the hatch. What is it for? I posted this on the NAWCC discussion board site and so far no-one has come up with the answer.

Why would anyone put a hatch on the bottom of this mantel clock?

Was the hatch added later on? There is a lighter colouring of the wood to the left of the green felt which seems to indicate that a hole was cut out later to accommodate the hatch.

A clasp on the other side of the hatch secures it in place and allows it to be removed.

Was the trap door a chamber to hide items? Why, when it simply opens up into the case interior.

And there’s more! Here is a view of the entire bottom showing a second cutout (see arrow) on the left side. Why go through all this trouble?

The clock is all back together and in the process of being regulated but I sure would like to solve this mystery. It has taught me one thing, always look at the bottom of a case.

I wonder if there are other Ingersoll-Waterbury clocks having this strange ‘geometry’ at the bottom.. And who was this guy Ross, anyway? I mean, ‘Would you, as a collector, inscribe something on your clocks?’

(PS: Just curious. I know nothing about clocks, mind you 🙂 )

LikeLike

Thanks for coming to my blog. I don’t think I would write something like this on the bottom of the clock but it is not uncommon to find initials and dates inscribed in various places on a clock, unusually inside the case. I can only assume that the person who wrote it was ether the previous owner or someone who serviced the clock for the owner. I have no any other Ingersoll-Waterbury clocks like this and I have even written to the curator of the Canadian Clock Museum and he does not know why the hatch was put there or why someone would write on the bottom.

LikeLiked by 1 person

I have an Ingersoll-Waterbury mantel clock similar to your pic. I am thinking of selling it but have no idea of its worth. Very good working condition and well preserved. Any advice is appreciated. Thanks!

LikeLiked by 1 person

This was a very common clock in the 1940s and while they are well made and will last a long time they are not worth much, unfortunately. An un-serviced clock might fetch 65CDN to 75CDN, while a serviced one (it’s been worked on, bushings replaced, cleaned and oiled) might sell for 125CDN or 150CDN. On top of all that the market for mechanical clocks is quite depressed but if you hang onto it for a couple of years you might see a rise in prices. Hope this helps.

Ron

LikeLike