A few changes have taken place since I last posted but the clock is still not 100% correct.

Some changes to note. The bottom right finial was repaired.

To the casual observer it looks impressive but a keen eye would reveal the repair. The middle finial is not attached as yet as there are still some minor cosmetic details that need to be addressed before I attach it to the base.

This past week I had contacted a local glass repair shop to make and install new 3 mm glass. Thicker than I thought but true to the original that is, if the glass that was broken was truly original. I say this because the glass shop noted that the previous glass was installed using finishing nails the shape, style and size of which would not have been available at the time (1902). So, putting new glass into the clock may not change the value since the glass that was broken during shipment was likely not original.

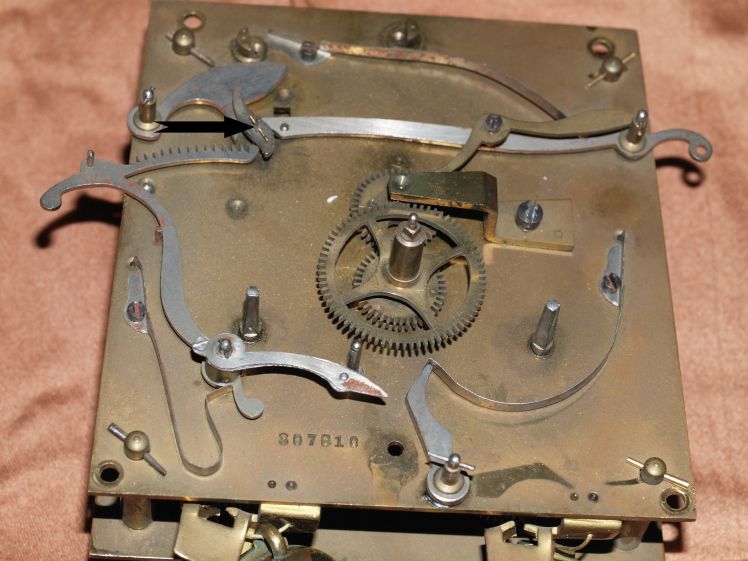

The movement was given a thorough cleaning and oiling including a nice polish to the plates. As all the striking levers are on the front plate they were very simple to re-attach. Re-assembly of the gears is quite easy compared to North American clocks I have worked on. No fiddling with levers and helper wires between the plates. Overall, the parts are of a very high quality as one would expect from the maker, Gustav Becker. There was no evidence of worn bushings or any other troubling areas and I did not see any other work required for this movement other than the obvious missing parts. Ultrasonic cleaning, pegging and polishing the pivots and cleaning the plates was all that was required. All parts are back in the clock save the star wheel lever and the hammer assembly which I do not have.

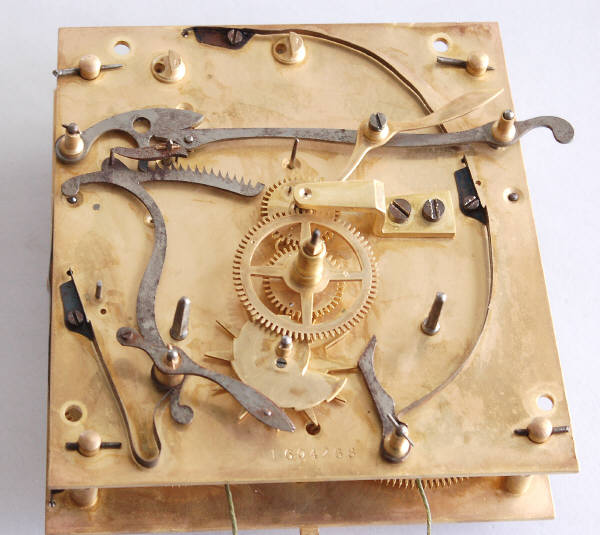

The above image is pulled from an online source. My apologies to the author of the photo. This GB Braunau movement shows the star wheel / snail gear which I am missing on my movement.

The movement below shows mine without the star wheel (bottom centre), and that is how I received it. I later received a “replacement” star wheel from the seller but unfortunately is does not fit. It might be from a later Braunau movement or a Silesia one, I am not sure. I am not going to force it, it really does not fit. The Braunau movement that I ordered online has not arrived as of this date but my hope is that I can interchange the parts that I am missing. We will see.

There are several other issues with this movement. As mentioned, there is no rod and hammer which is an obvious problem because without it the clock will not strike. It is my hope that the replacement movement will have one that I can adapt to my clock.

The next issue is the pin on the gathering pallet. The gathering pallet rotates to advance the strike rack. Despite straightening the pin on the pallet it still does not want to engage. My thinking is that the pin is either too short for whatever reason or that a piece of it likely snapped off at some point in the clock’s life. Again, I might be able to take a good one off of the replacement movement.

I also received a replacement dial bezel in the mail which is a definite improvement over the one that was dented in shipment. You can see the damage on the original bezel below.

Lastly, I have ordered 0.80 mm brass cable to replace the cat gut and a number 1 regulator crank which also did not come with the clock.

At this moment the time gears are working fine, the clock is ticking away and it actually tells the time.

All in all it has been an interesting project so far and some very good learning on my part.

After reading this, I have several notes I’d like to share with you. Before I say anything, please realize that I lean quite a bit more towards being a purist and conservator when it comes to antiques.

1. The finials are not normally glued in place. You mentioned something about the bottom finial and attaching it. The finials on Vienna clocks are usually only a friction fit so that they can easily be packed if the clock is to be moved. If the pegs are too loose, a simple slip of paper will usually do the trick.

2. Glass. Glass is very important in antique clocks, and the LAST thing you want to use (as a last resource) is modern/new flat glass. All antique clocks had handmade “wavy” glass, and most collectors can spot new glass a mile away (from another room). Old glass is easy to find, and often free. Most glass shops will cut old glass for you for a very nominal fee. My glass shop used to charge me 2$ to cut a few pieces for me. I get all my glass from old sash windows, and occasionally from antiques stores that have large piles of old window frames (they use these as mirrors and don’t use the clear glass). I’ve found some wonderful glass with small bubbles and imperfections.

Thin glass was normally used. No more than 2mm. The heavier glass will be harder-wearing on the already tiny door hinges.

3. Why does the spare star wheel not fit? Is it entirely the wrong shape, or is it simply that the mounting post doesn’t fit into the opening? Seems like an awful waste to scavenge a complete other movement for just a single piece, especially if you already got a spare. You don’t really explain other than “it doesn’t fit”. Most stock items (new parts) will have the same problems, so in a lot of cases, you need to be more creative and resourceful (enlarge holes, tighten holes, grind or modify profiles, etc).

4. I don’t understand why you would change a bezel because of a dent. Again, the damage wasn’t shown, but normally the original parts (like a bezel) are much better made than the cheap mass produced modern replacements. Could the dent not be pushed out and repaired? An obvious new bezel will affect value down the line. Personally, I’d much prefer a slightly damaged original bezel to a new one.

5. The pin on the gathering pallet should be easy to repair/replace. Just pull or tap it out and fit a new one.

6. A new hammer could also be made from scratch fairly easily (depending on the pattern). Replacements are also available. Most are simply a section of brass shaft with a square hole (which can be filed) a length of wire, and then a brass disc, or a hammer head (depending if it’s a Viennese style metal-on-metal strike, or a leather tipped hammer striking a vertical rod).

7. Animal gut is probably a nicer and more historic choice for a Vienna than brass cable. Cable is apparently stronger, but I don’t personally like the looks of it, and I also don’t trust it (wear eventually causes metal fatigue). The brass cable is also more likely to scratch and mark the winding drums over time. Personal preference. If you really want something a bit more invisible, you can also use 80lb test fishing line. It’s transparent, and since it’s plastic, it’s soft enough not to damage any of the brass parts.

LikeLike

Thanks JC. Your comments are very instructive.

I have included more photos, one showing the broken finial tip the damage to which I should have explained in more detail and the next showing the damaged bezel which is very unsightly and not repairable in my opinion. The replacement bezel looks like it was taken off a clock from the same period, not a new facsimile. This bezel was sent to me by the seller when I mentioned that the original bezel was damaged in shipment.

Your comments about the glass gave me pause to think. To be honest it never occurred to me to use an old window for replacement. It was a cheap fix and older glass is still an option.

The star wheel does not fit onto the post though it looks like it should. I cleaned the inside, applied lubrication but no luck. I will consider a modification. This wheel was sent to me by the seller when I mentioned that the clock was sent without one.

I will need to look into the gathering pallet and the hammer again as per your suggestions. The clock has a long rod gong.

Another product I looked at was synthetic gut and some folks use fishing line as you suggest. Not a huge thing to utilize something other than brass.

As you have correctly pointed out in your reply there is a difference between repair and restoration!

Thank you again.

Ron

LikeLike

Ron,

The finial repair turned out really well. I remembered seeing the broken one a while back.

Using new glass was one of my earliest clock repair mistakes. It can always be swapped out again, but it just ends up being wasted time and effort. It becomes even more of a problem when you start to deal with American clocks with painted glass. I always pick up discarded old windows on garbage day, so I have an almost endless supply of old glass (all of which was free) and I have my own professional stained glass cutter (tool). The problem is usually matching the “amount of desired waviness” to the clock in question. A clock from 1900 would have fairly good glass with some waviness and small bubbles (so pretty much any standard old window glass), while a clock from the early 1800s-1850 would have lots of waviness and large bubbles (some as big as 3/4″). The very old and very wavy stock is harder to find, because generally very imperfect glass was thrown away, and most of the houses here were built closer to the 1900s. There is also reproduction “seed glass” made today, but it looks way too fake with far too many bubbles and imperfections.

Your star wheel looks like it would fit with a bit of broaching to enlarge the hole. Do you own any cutting broaches? If not, you will soon find them rather indispensable. They are hexagonal tapered steel wires (mounted in pin vices) used to gently enlarge holes. All clock parts dealers carry them either individually or in sets. They are essential if you plan to do bushings.

A rod gong strike would require a leather tipped hammer. You can normally find spares in the junk pile (when you end up stockpiling one), or from parts suppliers. The only tricky bit would be the square stem that fits onto the rear arbour.

LikeLiked by 1 person

This is a topic that is near to my heart… Cheers!

Where arre your contact details though?

LikeLike

Click on “contact” at top of main page.

LikeLike

I’ve recently started a web site, the info you provide on this site has helped me tremendously. Thanks for all of your time & work.

LikeLike

Thanks for coming to my blog. Glad I was a help.

LikeLike